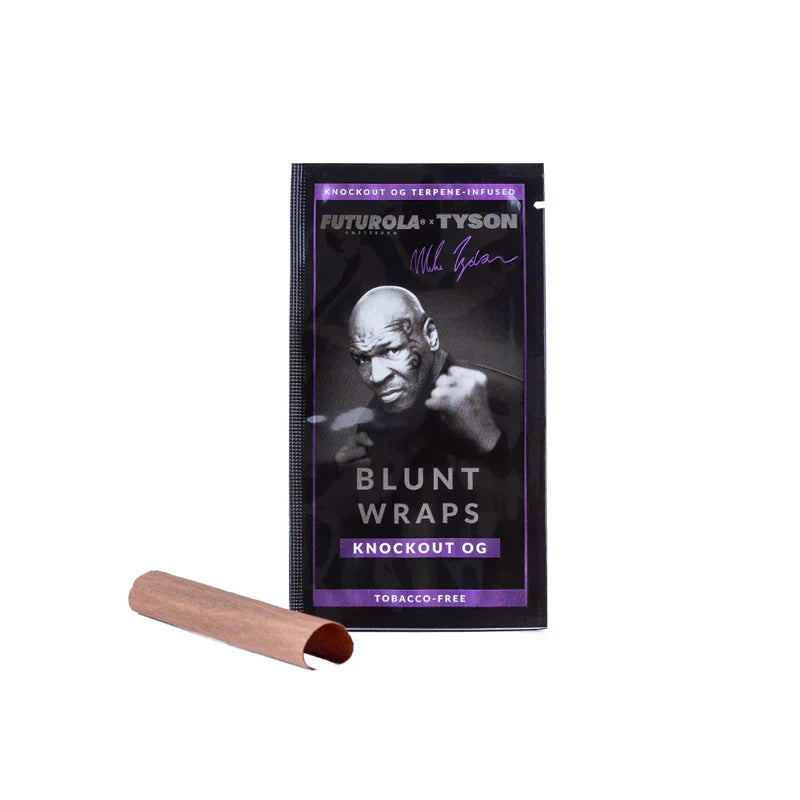

How Tobacco Free Blunt Wraps Are Made: From Raw...

Learn how tobacco free blunt wraps are made, from raw materials through shaping, drying, inspection, and packaging to ensure consistent quality and handling.

Read more

Tobacco Free Blunt Wraps for Pre Rolls: Why Are...

Discover why tobacco free blunt wraps are efficient for pre rolls, offering consistent handling, tool compatibility, and smoother preparation in structured workflows.

Read more

Tobacco Free Blunt Wraps vs Traditional Wraps: ...

Learn the key differences between tobacco free blunt wraps and traditional wraps, including consistency, handling, storage stability, and preparation performance.

Read more

Best Tobacco Free Blunt Wraps: What Makes FUTUR...

Explore what defines the best tobacco free blunt wraps and why FUTUROLA stands out through consistent materials, controlled design, and reliable preparation performance.

Read more

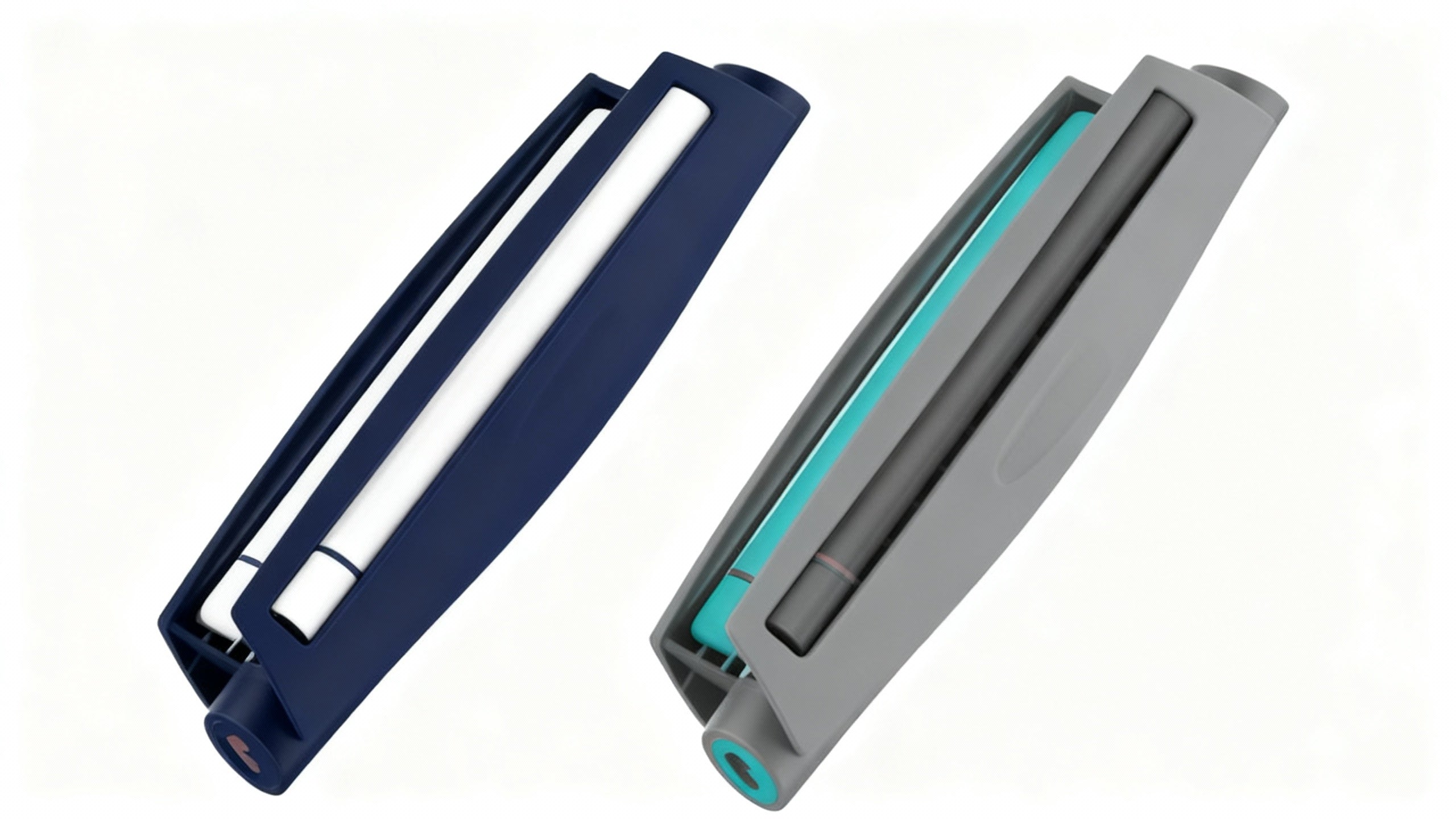

The Dutch Crown Device: Why Should You Buy One ...

The Dutch Crown Device has become a central tool in operations that rely on consistent cone production. As more facilities adopt automated filling systems, the need for precise finishing equipment ...

Read more

The Best Dutch Crown Device: Important Qualitie...

The best Dutch Crown Device creates clean, uniform folded tops on pre-rolled cones, eliminating the inconsistencies of manual sealing. Individuals and high-volume facilities rely on these devices f...

Read more

How to Use A Dutch Crown Device: An Easy to Fol...

A Dutch Crown Device automates the final sealing step for pre-rolled cones, creating a clean, uniform Dutch Crown instead of a twisted top. This controlled fold improves structural integrity, reduc...

Read more

What is a Dutch Crown Device: A Brief Overview

A Dutch Crown Device creates a clean, uniform Dutch Crown fold at the top of pre-rolled cones, improving structure, presentation, and long-term stability. This tool eliminates uneven manual folding...

Read more

Can Cone Rollers Handle Terpene-Infused Wraps?

Learn if cone rollers handle terpene-infused wraps. Covers equipment compatibility, settings adjustments, and troubleshooting for manual and automated systems.

Read more

How to Clean and Maintain Cone Rolling Equipment

Learn proper cleaning and maintenance for cone rollers: daily protocols, deep cleaning steps, and troubleshooting. Extend equipment life to 5-10 years.

Read more

Pros and Cons of Manual vs Automated Cone Roller

Compare manual and automated cone filling: production speeds, costs, and ROI. Learn which equipment matches your volume from 100 to 10,000+ daily cones.

Read more

Finding the Best Grinder to Maximize Pre-Roll C...

Find the right grinder for consistent cone packing. Learn how particle size affects fill quality, and match grinding capacity to your production volume.

Read more