You spend four hours filling 500 cones manually. Your fingers cramp. Your back hurts. Or you drop serious money on automated equipment that sits idle because you miscalculated your volume needs.

This choice determines your manufacturing capacity for years to come. Most operations make this decision based on incomplete information. They focus only on upfront costs and ignore production realities, hidden expenses, and scaling requirements. Understanding fundamental cone rolling tools and techniques provides essential context for evaluating whether manual or automated approaches best suit your operation.

The wrong choice costs you money and limits growth opportunities. This guide examines both manual and automated cone filling in response to real production demands. You'll learn how to match equipment to your volume needs, calculate actual costs beyond purchase price, and avoid common mistakes.

Disclaimer: Equipment prices, production capabilities, and regulatory requirements change frequently. All information represents general industry observations as of early 2025 and should be verified with current manufacturers and official sources before making purchasing decisions. Individual production results vary based on material quality, operator skill, and specific operational conditions.

Understanding Production Volume Requirements

Production volume drives every equipment decision you'll make. The gap between what you actually need and what you think you need often determines whether your investment succeeds or fails.

Start by measuring what you actually need on a daily basis. Not what you hope to produce someday. What you need right now, plus a reasonable 20-30% capacity buffer for demand fluctuations. Most people get this wrong by either buying too much capacity or not enough.

Small-Scale Operations Under 100 Cones Daily

Manual equipment works fine when producing under 100 cones daily for very low-volume internal use or micro-dispensary operations. Basic cone fillers and bump boxes handle this volume easily with one person managing the entire operation.

Equipment costs typically run from affordable manual tools to basic vibration devices. You get quality capability without overspending on automation you don't need. Training typically takes minimal time, usually under an hour, to achieve basic proficiency.

Mid-Scale Commercial Production

Daily production between 100 and 1,000 cones changes everything. Manual methods become a bottleneck fast. Your hands hurt. Your staff quit due to the tedious nature of their labor.

Semi-automated equipment makes sense here. Electric vibration systems handle 50-100 cones per cycle. You need one or two operators managing material loading and quality control.

Training takes a few days to reach full productivity. Space requirements increase with dedicated workspace and proper electrical infrastructure becoming necessary.

Industrial Manufacturing Scale

Production exceeding 1,000 cones daily demands industrial automation. Anything less creates constant stress and quality issues that affect output consistency.

Industrial systems handle thousands of cones per session with minimal human intervention. Multiple operators coordinate specialized production roles across material prep, machine operation, and quality monitoring.

Facility planning becomes non-negotiable. You need proper electrical infrastructure, ventilation systems, and dedicated storage space for both materials and finished products.

Peak Demand Planning

Peak demand often differs significantly from average production. If your average is 500 cones daily, but Friday hits 1,200, you need equipment capacity for 1,200 to avoid backorders.

Seasonal fluctuations crush businesses that ignore them. Pre-roll sales tend to spike around holidays and special events. Plan for peaks, not valleys, when sizing your equipment capacity.

Use actual historical data. Add modest growth projections, typically around 20%. Stop there. You can always upgrade later as actual demand increases.

Buffer capacity saves you during equipment downtime. Maintenance happens. Breakdowns occur. Having extra capacity prevents customer disappointment when unexpected issues arise.

Manual Cone Filling Methods and Applications

Manual filling serves specific purposes despite its limitations. Understanding when hand-filling makes sense versus when it holds you back determines whether this approach is suitable for your operation.

Hand-filling builds character. It also builds carpal tunnel. Know what you're getting into before committing for the long term.

Production Speed and Consistency Challenges

Manual hand-filling tops out around 10-20 cones per hour per person. That's roughly 80-160 cones during an eight-hour shift if you're experienced. New staff might hit half that rate initially.

Do the math on your volume needs. Can manual methods meet daily production targets? Consistency becomes nearly impossible at scale, with every cone differing slightly in packing density.

Weight varies between units. Customers notice these quality inconsistencies. Skill development can take weeks or months, and not everyone possesses the necessary dexterity.

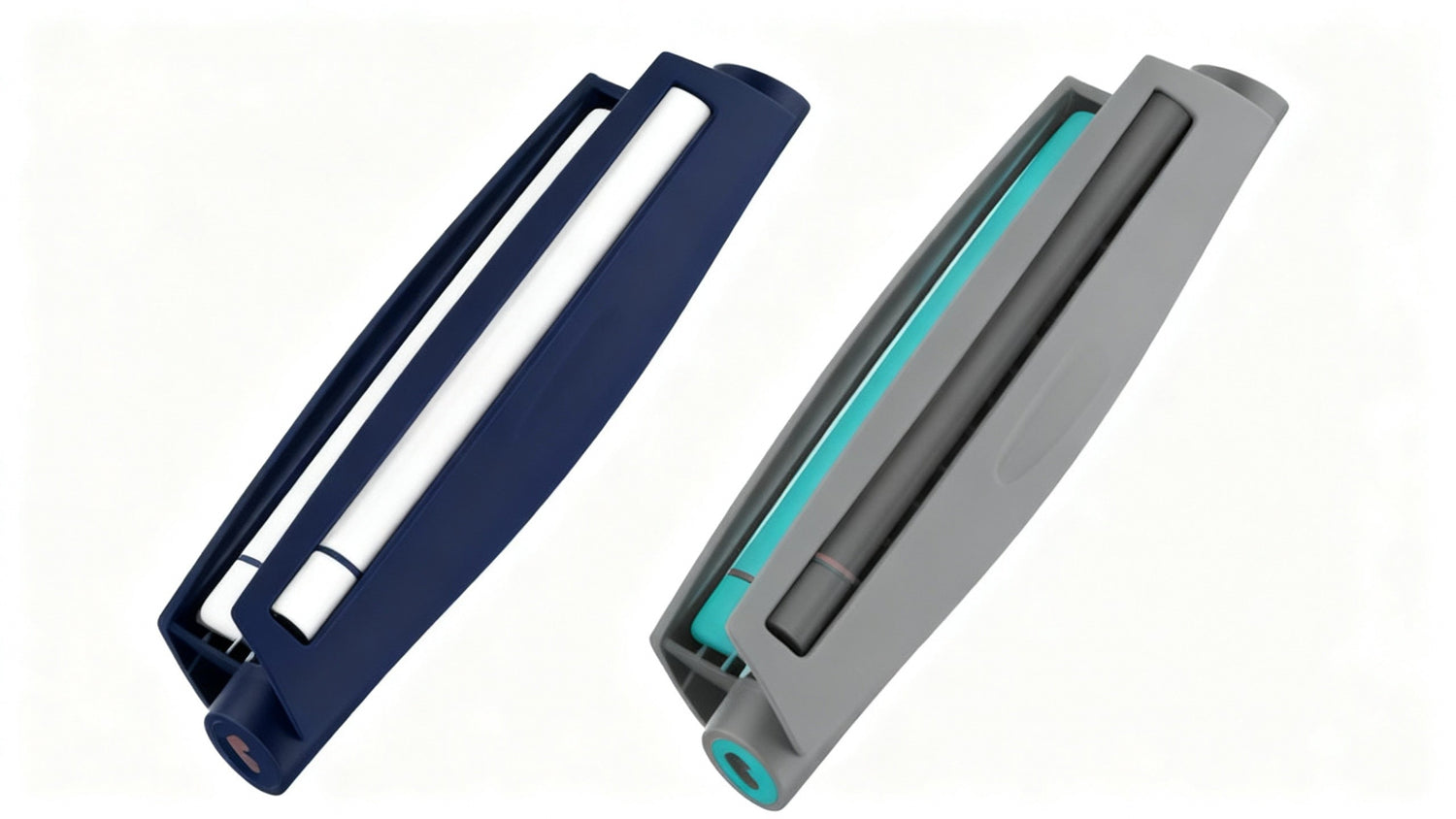

Manual Equipment Options

Bump boxes and vibration trays improve manual filling efficiency without removing the human element. You're still doing the work, but these tools reduce physical strain and repetitive motion injuries.

Simple cone loading devices aid in alignment and minimize spills. They don't solve the speed problem, but make the process more manageable.

Costs generally run from budget-friendly to moderate, depending on quality and features. Verify current pricing with manufacturers, as costs may vary by region and availability.

When Manual Methods Make Sense

Artisanal and craft production actually benefits from manual methods. You can market the hand-crafted angle authentically. Some customers pay premium prices for that distinction.

Small batch specialty products don't justify equipment investment. Limited releases, custom blends, and testing new offerings work well with manual approaches where flexibility takes precedence over speed.

Testing and R&D applications need manual control. You're experimenting with ratios, testing moisture levels, and trying different grinds. Equipment locks you into settings that limit experimentation and innovation.

Semi-Automated Equipment Solutions

Semi-automated systems bridge the gap between manual labor and full automation. These systems significantly boost production capacity while maintaining reasonable investment levels for growing operations.

This middle tier confuses people. You're not fully manual. You're not fully automated. You're somewhere useful in between, balancing human oversight with mechanical efficiency.

Electric Vibration Technology

Vibration technology improves consistency without removing human control entirely. The machine handles tedious packing work while you handle material prep and quality checks.

Batch capacity jumps dramatically with semi-automated vibration equipment. Studies suggest that production improvements of several hundred percent can be achieved over manual methods, although individual results vary based on operator skill and material preparation.

Operator involvement stays significant. You're loading cones, monitoring fill levels, checking quality, and running batches. Not just pushing a button and walking away.

Semi-Automated Equipment Features

Entry-level models from manufacturers like Futurola handle moderate batch sizes per cycle. Perfect for small to mid-size dispensaries with daily production needs in the hundreds of cones range.

Higher capacity models double or triple that output. Growing operations find these suitable for scaling up without jumping to industrial pricing levels.

Dutch Crown finishing devices complement these systems. You're finishing cones properly with clean crown closures and a professional appearance that customers can't help but notice.

Cone size compatibility covers standard, slender, and specialty sizes. One machine handles your entire product line, eliminating the need for separate equipment for different cone formats.

Investment and Returns

The initial investment for semi-automated systems varies considerably depending on capacity and features. Verify current pricing directly with manufacturers, as costs are subject to frequent change.

Labor cost reduction varies based on your current efficiency and wage rates. Calculate your specific numbers rather than relying on generic projections that may not reflect your situation.

Production speed improvements can vary substantially compared to manual methods. Individual results depend heavily on proper material preparation and operator training rather than equipment alone.

Quality consistency gains often matter more than raw speed increases. Every cone matches specifications. Customers get a consistent product every time. Complaints drop when quality becomes predictable.

Industrial Automation Systems

Industrial automation represents a major leap in production capability and investment requirements. These systems are suited for established operations with proven demand and the infrastructure to support high manufacturing volumes.

Serious production demands serious equipment. You're past the point where manual or semi-automated methods make financial sense for your volume requirements.

Automated Production Capabilities

Complete automation means minimal human intervention during actual production cycles. You're loading materials, setting parameters, and monitoring output. The machine handles the filling process independently. Understanding how cone rollers simplify production reveals the mechanical principles that enable industrial systems to achieve such dramatic efficiency gains.

Industrial systems can process substantial volumes per session. Cycle times are measured in hours for full production runs, processing thousands of units. Some operations run multiple machines in parallel for redundancy and increased throughput.

Advanced features often include automatic density control and integrated quality checks. Some models integrate with other production equipment to form a complete production line, encompassing grinding, filling, and packaging.

Capital Investment Considerations

Industrial equipment represents substantial capital investment with costs varying widely based on capacity, features, and integration requirements. This requires a comprehensive financial analysis, including ROI calculations and an assessment of the cash flow impact.

Facility requirements extend beyond the machine footprint itself. The electrical infrastructure may need upgrades to handle increasing power demands. You need proper ventilation and space for material staging areas.

Staff training investments increase with the complexity of the equipment. Plan for weeks of training and reduced productivity during learning curves as operators master the systems.

Maintenance programs become necessary rather than optional. Scheduled maintenance prevents downtime that can be costly when you're running high-volume production.

Decision Triggers for Automation

Production volume creates a financial tipping point where automation ROI becomes favorable. Industry observations suggest that this often occurs when consistently producing over 1,000 cones daily, although specific thresholds vary by business model.

Labor costs eventually exceed equipment costs in high-volume scenarios. When manual filling requires multiple full-time employees, automation often makes financial sense, though individual break-even calculations differ.

Quality consistency requirements from customers or regulations may force automation regardless of volume. Manual methods struggle to maintain tight tolerances that some customers demand.

Market demand scaling requires reliable production capacity. You can't grow your business without infrastructure to consistently deliver increased volume.

Material Handling and Quality Control

Material preparation has a significant impact on equipment performance across all automation levels. The same machine produces different results depending on how well you prepare your flower material.

Moisture Content Management

Moisture content matters more than most people realize. The sweet spot typically falls within a moderate range that varies slightly depending on the variety's characteristics.

Too dry and material crumbles during handling. Too sticky and it clumps together, preventing even distribution. Semi-automated equipment handles varying moisture levels more effectively than manual methods, thanks to consistent vibration and pressure.

Fully automated systems often tolerate a broader range of moisture levels. Adjustable settings and sensors detect problems before they significantly impact production quality.

Storage and handling best practices prevent moisture problems before production starts. Proper humidity control and sealed containers help maintain consistency across batches.

Grind Consistency Standards

Manual filling works with looser grind specifications because you're adjusting by feel and compensating with technique. This flexibility allows for material variation that would jam automated equipment.

Semi-automated equipment needs tighter grind specifications to function properly. Too coarse and material won't settle correctly. Too fine and it clumps, creating uneven density.

Industrial equipment requires precise grinding because you're setting specific parameters. The machine executes those settings consistently without adjustment capability during runs.

Achieving proper particle size requires quality grinding equipment. Cheap grinders produce inconsistent results, which can create downstream production problems and equipment jams.

Density Control Across Equipment Types

Manual packing density varies by operator skill, material characteristics, and fatigue level over shifts. Consistency becomes challenging across hundreds of units, even with experienced staff.

Semi-automated equipment provides measurable consistency improvements. Every cone receives a similar vibration time and compression force, thereby reducing unit-to-unit variation.

Fully automated systems deliver precision density control through programmed cycles. Settings are locked in via digital controls, ensuring every cone matches specifications within tight tolerances.

Variety-specific adjustments still matter with automation. Different varieties pack differently, even with identical equipment settings, so document what works for each variety.

Selecting Equipment for Your Operation

Equipment selection depends on matching your actual production needs with realistic budget constraints and facility capabilities. Mismatches in any of these areas lead to expensive mistakes.

Capacity and Business Type Alignment

Manual methods are suitable for use with under 100 daily cones in personal use and micro-dispensary scenarios. Equipment costs stay minimal, and learning curves remain manageable for occasional production.

Semi-automated equipment, such as Futurola's Knockbox series, is well-suited for operations that produce hundreds to approximately 1,000 cones daily. Small to medium-sized dispensaries and growing cannabis businesses find these systems strike a balance between capability and investment requirements.

Industrial automation makes sense for established manufacturing operations beyond 1,000 daily units. These businesses have proven demand and infrastructure supporting serious volume production.

Total Cost of Ownership

Purchase price represents just the beginning of equipment costs. Most businesses underestimate total ownership expenses when excluding consumables, maintenance, electricity, training, and facility modifications.

Consumable supplies accumulate over the equipment's lifespan. Loading trays wear out. Attachments break. You're reordering regularly, and these costs compound over years of operation.

Electricity consumption varies significantly between different equipment types. Industrial machines pull substantial power. Calculate your actual costs based on local rates and expected usage patterns.

Maintenance schedules cost money even when nothing breaks. Preventive maintenance, including regular cleaning, calibration, and inspection, prevents expensive emergency repairs that halt production.

Strategic Planning Factors

Calculate total costs, including labor, space, and hidden expenses beyond the equipment purchase. Total ownership cost determines actual profitability over the equipment's lifespan.

Match equipment capacity to realistic demand with appropriate buffer capacity. It is better to upgrade twice than to overbuy once and tie up capital in unused capacity.

Consider scalable solutions within one equipment ecosystem. Starting smaller and upgrading as demand increases often beats jumping straight to equipment you can't fully utilize.

Factor in training time and staff requirements realistically. Equipment sits idle during training periods. Budget for reduced productivity while staff learns new systems properly.

Verification and Due Diligence

Verify current equipment prices and capabilities directly with manufacturers before making a commitment. Specifications change. Prices fluctuate. Features improve with newer models.

Request demonstrations when possible before major purchases. Seeing production in action reveals details no specification sheet captures about workflow and practical operation.

Calculate ROI based on your specific labor costs and volume numbers. Generic calculations mislead because your wage rates, production volume, and operational efficiency all differ from averages.

Contact manufacturers directly for guidance on selecting the appropriate equipment. They've seen thousands of operations and know what actually works for different business scenarios and volume levels.

Regulatory and Regional Considerations

Regulations affect equipment choices in ways that vary significantly by jurisdiction. Understanding your local requirements prevents expensive mistakes and compliance issues.

Compliance Requirements

Regulations change frequently and vary by jurisdiction. Always verify current local requirements before making equipment purchases that may need specific certifications or features.

Some jurisdictions have specific equipment requirements beyond basic safety standards. Permits, inspections, or approval protocols may apply depending on your location and production scale.

Budget for compliance costs when planning equipment investments. These expenses add to total ownership costs and vary widely based on local regulations.

Safety equipment requirements scale with the level of automation. Guards, emergency stops, and proper training affect both upfront costs and ongoing insurance rates for your operation.

Getting Your Equipment Investment Right

Equipment decisions require balancing immediate production needs against future growth potential without overcommitting resources to unused capacity.

Manual methods are suitable for small operations and specialty production where flexibility is more important than speed. Semi-automated systems bridge the gap for growing businesses that have outgrown manual filling but don't yet require industrial-scale solutions.

Industrial automation supports significant manufacturing volumes for established operations with proven demand and adequate infrastructure.

Calculate your actual daily production needs, including peak demand periods. Add a reasonable buffer capacity to account for equipment downtime and demand spikes. Match equipment to that realistic number rather than optimistic projections.

Consider total ownership costs, including the purchase price alone. Labor savings, space requirements, electricity consumption, maintenance expenses, and consumables all impact profitability over equipment lifespan.

Plan facility modifications before equipment arrives. Electrical upgrades, workspace reconfiguration, and permit approvals take time that shouldn't delay production startup.

Contact manufacturers directly for current pricing and capability information. As a leading cone rolling equipment provider, Futurola has worked with thousands of operations and understands what actually works for different business scenarios and production volumes.

Individual production results vary based on material quality, operator skill, facility conditions, and operational practices. Always verify all specifications and consult with equipment manufacturers before making final purchasing decisions. This analysis is for informational purposes only and should not be considered business or financial advice.

LEAVE A COMMENT

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.