A cone rolling machine can last 5-10 years with the right care. Or fail within 12-18 months due to neglect and residue buildup. The difference comes down to consistent cleaning and maintenance.

Most cone roller equipment problems can be directly attributed to material residue buildup. Sticky surfaces cause jamming. Material accumulation leads to tearing. Inconsistent performance ruins production quality.

All are preventable with regular care.

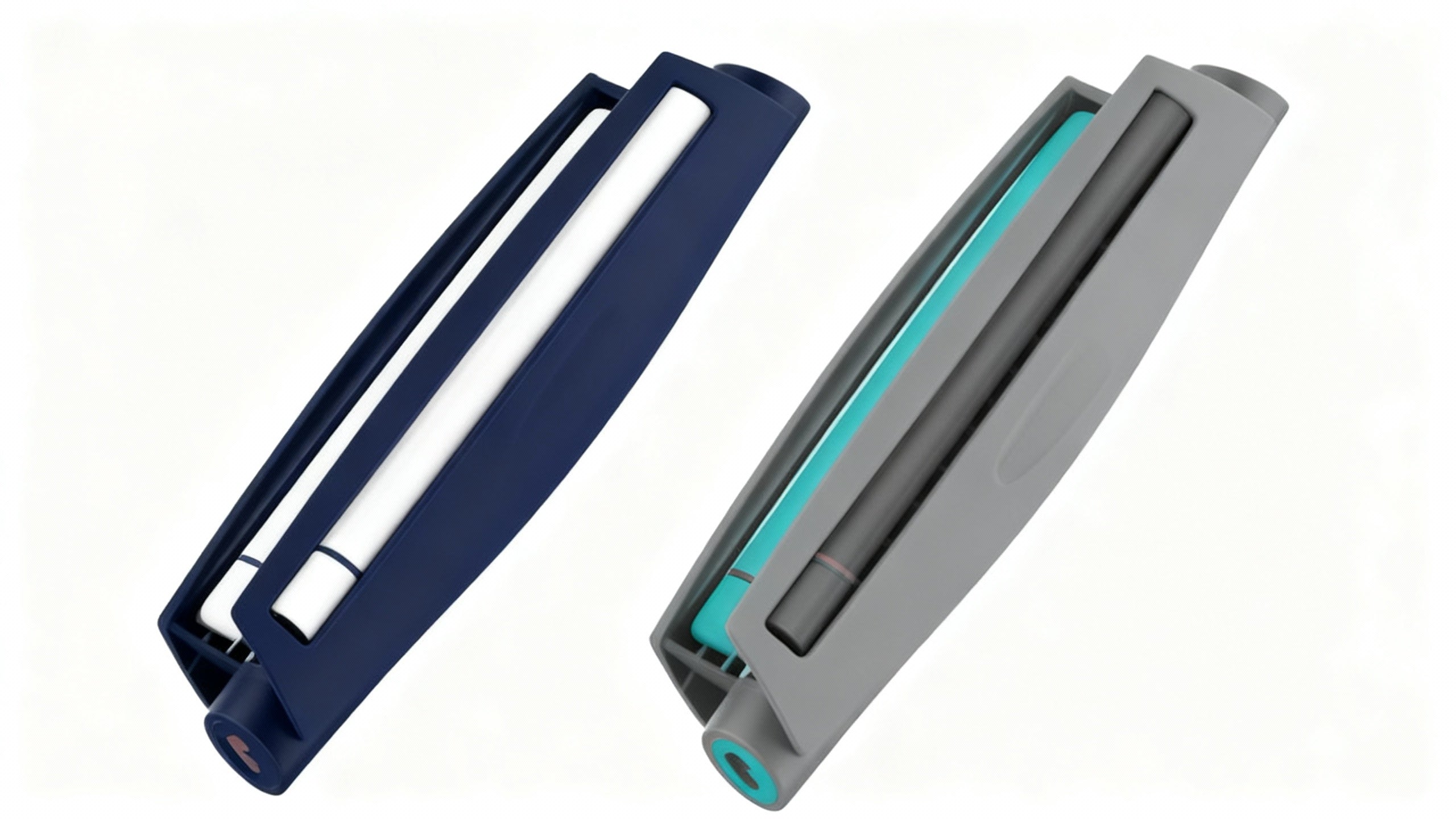

Both manual hand-rolling devices, such as the Dutch Crown, and commercial automated equipment, like Knockbox filling systems, require attention. Your Dutch Crown requires different care than a Knockbox 300. But the principle stays the same.

Clean equipment performs better and lasts longer. Mastering cone rolling tools and techniques ensures you're getting maximum value from properly maintained equipment, combining operational excellence with longevity.

This equipment maintenance guide covers daily cleaning protocols, deep maintenance procedures, usage-based schedules, and troubleshooting for maintenance-related problems. You'll learn what to clean, how often, and which products work without causing damage.

These aren't generic maintenance tips. This is what protects your investment and ensures consistent production.

Disclaimer: Equipment specs and recommended maintenance procedures vary by manufacturer and model. Based on 2025 data and general equipment care principles. Always consult the equipment manufacturer's guidelines before cleaning your specific model.

Why Regular Maintenance Actually Matters

Skipping maintenance seems like saving 10-15 minutes per day. Until your cone roller fails during a critical production run. Halting operations for 2-4 hours for emergency cleaning and repairs.

Prevention takes minutes. Repairs take days and cost way more.

How Residue Buildup Kills Performance

Flower material residue accumulates on every surface of equipment during normal use. Sticky resinous compounds. Fine plant particles. Terpene oils.

Buildup rates vary from 0.1 to 0.5mm thickness per 100 cones processed. Depends on the material's moisture content.

Rolling aprons collect sticky deposits. Grooves trap compacted material. Loading areas develop layers of buildup.

This residue interferes with smooth operation. Papers stick to surfaces instead of sliding cleanly. The material doesn't compress evenly. Cones jam in holders.

I've watched this happen slowly over 200-500 rolling cycles. Subtle enough that operators don't notice a consistent decline. Until the jamming frequency increases by 40-60%.

Paper tear rates double from baseline levels. By then, you're already behind.

The Cost of Neglected Equipment

Complete equipment failure from neglect stops production entirely. You're looking at 2-4 hours of downtime. Lost production capacity of 200-400 cones. Revenue losses of $400-1,200.

I've watched operators frantically clean neglected machines under deadline pressure. Rush cleaning misses problem areas. The cycle repeats.

Equipment replacement costs $200-$ 2,000, depending on the model. Preventive maintenance? A $15 bottle of isopropyl alcohol and 15 minutes daily.

Do the math. Hundred-dollar repair bills versus fifteen-dollar prevention. New rolling aprons cost more than months of cleaning supplies.

Quality suffers before equipment fails. Inconsistent fills. Paper tears. Uneven density. Your finished products reflect the condition of the equipment.

Cross-contamination becomes a problem, too. Operations handling multiple varieties see residue from one material mix with the next. Product purity suffers.

What Right Maintenance Delivers

Well-maintained cone rolling equipment lasts 3-5 times longer than neglected machines. Manual rollers serve 8-10 years. Commercial systems reach 5-7 years of reliable operation.

Mechanisms stay smooth. Components wear evenly, rather than developing stress points.

Production consistency improves dramatically. Each cone comes out identical to the last. Fill quality remains consistent across the entire batch.

Downtime drops to nearly zero. No surprise failures. No emergency cleaning sessions. No production delays from equipment problems.

Your equipment investment returns way more value. A $300 manual roller maintained right costs $30-50 annually in supplies. Produces 10,000-15,000 cones over 5+ years.

Neglected equipment? $150-200 annual replacement costs. Failing every 18 months.

Daily Cleaning Protocols for Manual Cone Rollers

Manual cone rollers need attention after every use. Quick daily cleaning prevents buildup that becomes difficult to remove later. These procedures take five minutes but prevent hours of problems.

Quick Clean After Each Rolling Session

Remove all loose flower material from loading areas immediately after finishing, while residue remains fresh. Before it oxidizes into harder-to-remove sticky deposits.

Trust me on this timing. Fresh residue wipes away easily. Wait an hour? That residue oxidizes into sticky hell.

I've seen people ignore this. Then they spend 30 minutes scraping what should've taken 30 seconds to wipe.

Gently tap the device to dislodge any stuck particles. Use a soft brush to sweep out corners and grooves.

Wipe down all contact surfaces with a clean, dry cloth. Focus on areas where paper comes into contact with equipment. Remove any visible sticky residue.

Check for visible material accumulation. If you spot buildup, move beyond quick cleaning to deeper procedures. Catching problems early matters.

Cleaning Rolling Aprons and Bands

Remove rolling aprons carefully without stretching or deforming them. Material stretched beyond 10-15% of its original dimensions loses elasticity. Creates uneven pressure distribution during rolling.

Most designs lift off easily once you know the attachment mechanism. Never force components.

Apply a 90% or higher concentration of isopropyl alcohol to a clean, lint-free microfiber cloth. Then wipe apron surfaces thoroughly on both sides.

The alcohol dissolves resin without damaging most materials. I prefer 99% whenever I can find it. Evaporates fast. No waiting around.

Let aprons air dry completely before reinstalling. Moisture trapped under aprons creates problems. Give them 10-15 minutes of open-air time.

Inspect aprons while cleaning. Look for stretching, wear patterns, or surface damage. Small problems can grow into failures if left unaddressed.

Maintaining Cone Grooves and Guides

Ground flower material compacts into the groove corners during normal rolling. Creates hardened deposits within 50-100 uses. These spots need targeted attention.

Cotton swabs work well for detailed work. Use non-abrasive cleaning tools that remove residue without scratching delicate surfaces.

Wooden toothpicks work great. Soft plastic scrapers similar to credit cards. Nylon brushes handle stubborn deposits safely.

Metal tools leave scratches that catch paper later. Don't use them.

Check groove alignment while cleaning. Components shift slightly over time. Misalignment causes inconsistent results and paper damage.

Paper fibers accumulate differently from material residue. They create fuzzy buildup that feels different. Address this with gentle brushing rather than scraping.

Dutch Crown Device Care

The Dutch Crown's cone-shaping mechanism has unique cleaning needs. Access the internal area by following the disassembly sequence in your manual.

Hard-to-reach internal areas need attention. Use cotton swabs dipped in isopropyl alcohol. Patient methodical cleaning prevents performance degradation.

Don't skip these spots because they're difficult. The buildup there affects performance noticeably. Spend 3-5 minutes on these hidden surfaces.

Moving parts need occasional lubrication. Use food-grade lubricant sparingly on pivot points. Too much lubricant attracts dust and material.

The cone support structure also needs attention. Clean where cones rest during rolling. Sticky residue here transfers to finished products.

Deep Cleaning Procedures for Manual Equipment

Weekly deep cleaning addresses buildup that daily maintenance misses. This approach prevents long-term performance degradation. Set aside 30 minutes for thorough deep cleaning.

Weekly Complete Cleaning Steps

Disassemble removable components following manufacturer guidelines. Keep small parts organized in labeled containers. Screws, washers, springs.

Take photos before disassembly if helpful. Makes reassembly easier.

Soak removable non-electrical components in a 90%+ concentration of isopropyl alcohol for 10-15 minutes. Use a glass or stainless steel container.

This dissolution process breaks down sticky resinous bonds at the molecular level. Softens deposits for easier removal.

Gently scrub soaked parts with a soft brush. Remove all visible residue before rinsing. Check crevices and corners carefully.

Reassemble everything and test the operation before returning to production. Components should move smoothly without binding. Alignment should feel right.

Cleaning Products That Work

Isopropyl alcohol at 90-99% concentration works best for dissolving resin. Higher percentages, such as 99%, evaporate within 30-60 seconds, leaving no residue.

Lower concentrations around 70% leave more water behind. An extended drying time becomes necessary.

Mild dish soap and warm water are sufficient for general cleaning. This combination removes oils and light residue without harsh chemicals.

Soft-bristled brushes prevent surface scratching. Toothbrushes work well for most applications. Avoid abrasive pads or steel wool.

Never use acetone, nail polish remover, paint thinner, or harsh chemical solvents on plastic or rubber components. These chemicals can weaken or dissolve certain materials. Stick with isopropyl alcohol.

Dealing With Heavy Resin Buildup

Normal cleaning fails when the residue gets too thick. This occurs due to skipped maintenance or the presence of sticky materials.

Extended soaking in isopropyl alcohol helps dissolve heavy buildup. Leave heavily affected components submerged for 2-4 hours. Overnight soaking handles severe cases.

I've seen equipment neglected for weeks. The buildup oxidizes and hardens. Takes overnight soaking to fix.

Gentle scraping removes softened buildup without damaging underlying surfaces. Use plastic scrapers designed for non-stick cookware. Work slowly and carefully.

Prevent future heavy buildup by increasing cleaning frequency. If buildup returns quickly, your maintenance schedule needs adjustment.

Automated Equipment Cleaning

Commercial filling equipment operates under different demands than manual rollers. Higher volume means more residue. Complex mechanisms need attention. But the payoff in consistent production makes maintenance worthwhile.

Knockbox Series Daily Maintenance

Empty all flower material completely from vibration trays after each production run. Material residue left sitting overnight oxidizes. Bonds more strongly to metal surfaces.

Becomes 40-60% harder to remove than fresh residue. I learned this the hard way. Don't repeat my mistake.

Tap trays to dislodge stuck material. Wipe down all external surfaces where material contact occurs. Vibration spreads fine particles everywhere.

Cone holders need daily removal and thorough cleaning with isopropyl alcohol. Material trapped inside holders causes cone feeding problems. Jamming. Inconsistent fill density.

Remove them from the machine. Clean thoroughly. Check inside holders for compacted material.

Visual inspection catches problems early. Look for loose fasteners, worn components, or unusual residue patterns. Address issues immediately.

Deep Cleaning Commercial Equipment

Weekly maintenance goes beyond daily procedures. This deeper cleaning maintains peak performance. Plan for equipment downtime during this process.

Access internal mechanisms in accordance with manufacturer safety protocols. Always disconnect electrical power at the source. Wait 2-3 minutes for capacitors to discharge.

Make sure moving parts have completely stopped before opening equipment housings. Safety first. Always.

Use compressed air to blow out accumulated dust and particles. Motor housings need external cleaning only. Never introduce liquids into electrical components.

Compressed air and dry wiping handle these areas. Reassemble the device carefully and run test cycles before returning it to production.

Listen for unusual sounds. Check that all mechanisms operate smoothly.

Cleaning Attachments and Accessories

Cone loaders accumulate material at loading points. Remove and clean these frequently. Stuck material in the loaders causes feed failures.

Spill trays catch overflow during filling. Empty and wipe these daily. Built-up material in trays contaminates subsequent batches.

Mix trays need careful cleaning to prevent cross-contamination. Wash thoroughly between different materials. Dry completely before reuse.

Check power adapters and connections for dust buildup. Blow out connection points with compressed air. Dirty connections cause intermittent electrical problems.

Maintenance Schedules Based on Usage

One-size-fits-all maintenance doesn't work. Light home use needs different schedules than commercial operations. Match your maintenance intensity to usage patterns.

Light Use Plans (Under 50 Cones Daily)

Quick 5-minute cleaning after each rolling session handles most maintenance needs. Wiping contact surfaces and removing loose material prevents 80-90% of buildup-related problems.

Deep cleaning the equipment weekly helps maintain its good condition. Disassemble and clean components thoroughly. Inspect for wear during deep cleaning.

Monthly inspections catch developing problems. Check all mechanisms for unusual wear. Test component fit and alignment.

Store equipment right between uses. Cover it to prevent dust accumulation. Keep it in climate-controlled spaces when possible.

Medium Volume Operations (50-500 Cones Daily)

Daily thorough cleaning becomes important at medium production volumes. Material buildup accumulates 5-10 times faster than light-use operations.

Requires 15-20 minute cleaning sessions after each production run. Material buildup happens faster. Quick cleaning after each run prevents problems.

Deep cleaning twice weekly maintains performance. Increased usage accelerates residue accumulation. More frequent thorough cleaning compensates.

Keep spare parts on hand for quick replacements. Rolling aprons wear faster with higher volume. Having backups prevents downtime.

Quality control checks verify maintenance effectiveness. If cone quality varies, maintenance might be inadequate. Adjust schedules based on results.

High-Volume Commercial Maintenance (500+ Cones Daily)

Multiple cleaning checkpoints throughout each production day make sense. Operations producing 500-2,000+ cones daily need maintenance breaks every 2-3 hours.

Every 200-300 cones prevents buildup that could halt production during peak operating periods. Clean between different materials always. Clean during production breaks.

Preventive replacement schedules avoid failures during runs. Track component usage. Replace parts before they fail.

Backup equipment strategies protect production capacity. Having a second roller available during maintenance prevents bottlenecks.

Document all maintenance activities for compliance and quality tracking purposes. Records reveal patterns. They prove due diligence for regulatory purposes.

Component Inspection and Replacement

Parts wear out eventually. Catching wear early prevents failures and maintains quality. Know what to look for and when replacement makes sense.

Recognizing Wear Patterns

Rolling aprons stretch with repeated use. Check dimensions every 500-1,000 rolling cycles against new replacement aprons. Noticeable stretching means replacement time.

Surface scratches affect how paper slides across components. Light scratches are normal. Deep scratches that catch your fingernail cause paper tears.

Mechanical components develop increased friction resistance over time. From wear, misalignment, or residue buildup.

If moving parts feel harder to move than when new, clean them thoroughly first. Replace worn components if resistance persists after cleaning. However, many performance issues stem from operator error rather than equipment wear. Avoiding common cone roller mistakes prevents unnecessary component replacement.

Alignment drifts from repeated use. Components that don't line up right need adjustment or replacement. Misalignment causes quality problems.

When to Replace vs Repair

Calculate component replacement costs in relation to repair labor time and complexity. Simple, inexpensive parts, such as rolling aprons ($15-$ 25) or filter holders ($10-$ 20), deserve immediate replacement.

Parts availability matters. If replacements ship quickly, replacement beats repair. Hard-to-source parts justify more repair effort.

Some components can't be repaired well. Rolling aprons don't mend. Stretched material needs replacement.

Warranty coverage influences decisions. If parts are under warranty, contact the manufacturer. DIY repairs may void coverage.

Maintaining Spare Parts Inventory

Stock rolling aprons for your specific equipment model. These wear faster than other components. Having spares prevents downtime.

Keep common fasteners and small parts available. Losing a small screw shouldn't stop production.

Store spare parts in sealed containers. Protect them from dust, humidity, and temperature extremes. Degraded spares defeat their purpose.

Rotate spare parts inventory. Use the oldest spares first. Check stored parts occasionally for condition.

Troubleshooting Maintenance-Related Problems

Many equipment problems stem from inadequate maintenance. Before assuming mechanical failure, investigate cleaning and maintenance as potential causes. This approach saves money and downtime.

Solving Jamming Issues

Hidden residue accumulation causes 70-80% of equipment jamming problems. Material gets trapped in places you don't see during routine cleaning.

Internal channels behind removable components. Inside cone holder cavities that operators don't see during surface-level cleaning.

Clean areas you've been missing. Remove components to access hidden surfaces. Use flashlights to spot buildup in shadows.

Material type affects cleaning needs. Sticky materials require more frequent maintenance. Adjust your schedule based on what you're processing.

Guy I know runs really sticky material through his Knockbox. Cleans it twice as often as the manual says. Never have jamming problems.

His buddy follows the basic schedule with the same material. Equipment jams constantly. Wonders why.

Fixing Uneven Filling Problems

Residue creates distribution problems by blocking the flow of material. Partially clogged areas direct material unevenly.

Clean with distribution in mind. Focus on the pathways through which material travels during the filling process. Nothing should obstruct smooth flow.

Check for areas that consistently show more buildup. These areas require special attention during routine cleaning. They're likely flow restriction points.

Alignment issues also cause uneven filling. Clean thoroughly first. If problems continue, check mechanical alignment.

Addressing Paper Tearing

A sticky, resinous residue catches the paper edges during the rolling process. Even microscopic deposits of 0.01-0.05mm thickness create enough friction to tear thin rolling papers.

Small rough spots tear paper under tension. Clean all paper-contact surfaces meticulously. Even tiny sticky spots cause tears.

Use adequate alcohol to dissolve all residue. Surface roughness from buildup creates friction. Papers tear at high-friction points.

If tearing persists after cleaning, inspect surfaces for damage. Scratches or rough spots from wear need to be addressed. Light polishing helps minor surface issues.

Eliminating Cross-Contamination

Complete cleaning between different materials prevents cross-contamination. This matters for quality and compliance.

Deep clean before switching materials. Quick cleaning isn't sufficient when purity is a concern. Take time for thorough cleaning.

Some operations use dedicated equipment for each variety. Color-coding or labeling prevents mix-ups. This approach eliminates contamination risks.

Environmental and Storage Considerations

Where and how you store equipment can significantly impact your maintenance needs. Environmental factors accelerate wear or cause problems. Smart storage prevents issues before they start.

Storage Between Uses

Cover the cone rolling equipment with breathable fabric covers when not in use. Dust settles on everything exposed. Covers keep equipment cleaner between uses.

Control relative humidity in equipment storage areas to 40-60% RH. Humidity levels above 65% promote mold growth of mold on organic residues.

Levels below 35% cause rubber and silicone components to dry out and crack. High humidity affects materials and mechanisms. Rust develops on metal components in damp conditions.

Store at moderate temperatures. Extreme heat or cold affects materials. Plastics become brittle in cold. Adhesives degrade in heat.

Keep equipment away from direct sunlight. UV exposure damages many materials over time. Store in shaded or enclosed spaces.

Environmental Factors Affecting Maintenance

Humid production environments above 60% relative humidity increase maintenance cleaning frequency needs by 30-50%. Moisture makes resin tackier and more adhesive.

Buildup accumulates faster on equipment surfaces. Creates stronger bonds that require more aggressive cleaning to remove.

Temperature affects how residue behaves. Warm conditions make the buildup tackier. Cold makes it more brittle but harder.

Dusty areas contaminate equipment constantly. Additional cleaning becomes necessary just to combat environmental contamination.

Good airflow helps. Moving air reduces moisture accumulation. It also helps the equipment dry faster after cleaning.

Your Equipment Maintenance Action Plan

Both manual devices and commercial systems respond to consistent care. The difference between years of reliable service and premature failure comes down to attention to detail.

Prevention beats repair every time. Five minutes daily prevents hours of emergency cleaning. Maintenance costs pennies compared to replacement.

Equipment ranging from Dutch Crown manual cone rollers to Knockbox commercial automated filling systems all benefit from the same fundamental principle. Clean daily. Inspect weekly. Maintain proactively.

The specific procedures vary. But the commitment to care stays constant.

Futurola's experience in manufacturing equipment since 1996 demonstrates the benefits of consistent care. As a trusted cone rolling equipment manufacturer with decades of innovation, Futurola designs equipment for longevity that still needs maintenance to reach its potential.

View maintenance as a means of protecting your production capacity. Your equipment enables your business. Maintaining it maintains your ability to serve customers.

Product quality starts with equipment condition. Clean equipment produces consistent results. Neglected equipment produces frustration and waste.

Start with these fundamentals: clean after every use, deep clean weekly, inspect components monthly, replace parts before they fail, and document everything that matters.

Your investment in quality equipment deserves care that protects it. Take the time to clean right. The results are years of reliable production and consistent quality.

This guide is for informational purposes only. Equipment designs and recommended care procedures vary by manufacturer and model. Always follow the maintenance guidelines provided by your equipment manufacturer. Individual maintenance needs depend on usage frequency, environmental conditions, and the design of the equipment.

LEAVE A COMMENT

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.