You fill 100 pre-rolled flower cones and half pack unevenly. They perform poorly. Some fall apart during handling. The problem isn't your filling technique or your cones.

Your grinder produces inconsistent particle sizes ranging from powder to large chunks. This sabotages every step of your cone packing process, from material flow through loading equipment to final product density control.

Most grinder guides focus on vaporizing or personal use. They completely ignore how grind consistency determines cone packing success and the quality of pre-roll manufacturing. The wrong grinder creates particles too large for even filling. Too fine for proper airflow. So inconsistent that your cones become unpredictable products with variable consumption rates. While proper grinding prepares material for filling, mastering cone rolling tools and techniques ensures you maximize that preparation through efficient packing methods and equipment maintenance.

This guide connects grinding directly to cone packing performance. You'll learn which grinder types work for different cone sizes, how to match grinding capacity to your production volume, and what particle consistency actually means for filling efficiency.

Disclaimer: Grinder prices, specifications, and availability are subject to change frequently. All information represents general industry observations as of early 2025 and should be verified with current manufacturers before making purchasing decisions. Individual grinding results vary depending on the flower's moisture content, material characteristics, and the operator's technique.

How Grind Consistency Affects Cone Packing Performance

Particle size controls everything about cone performance. Ignore this and you're wasting material, time, and customer goodwill.

Even particle distribution fills cones uniformly with consistent density and weight across production runs. Simple as that. Inconsistent grinding, producing mixed particle sizes, creates air pockets and gaps throughout the cone, resulting in uneven density.

Particle size affects how material flows through cone loaders and vibration-based filling equipment. Too fine and it clogs filling mechanisms. Too coarse and it won't settle properly under vibration or gravity-based packing systems.

Optimal Particle Size Range

Fine dust clogs during packing. You're stopping production to clear jams. Large chunks prevent even distribution. Material bridges across the cone opening instead of falling through.

The range for most standard cones with moderate diameter openings is medium to fine consistency, with particles between 1-2mm, for balanced flow and packing density. Think coffee grounds texture with visible individual particles that flow freely.

Not powder dust that clumps and clogs. Not pebbles that bridge and jam.

Heat and Terpene Preservation

High-RPM grinders with a metal blade generate heat during grinding. That heat can degrade compounds you're trying to preserve. Blade speed friction may destroy valuable terpenes before you pack.

Low-RPM systems with high-torque approaches preserve quality by minimizing heat generation. Slower speeds reduce frictional heating. Less friction prevents thermal degradation of volatile compounds.

This impacts the final cone aroma and flavor. Customers often notice the difference between properly ground flower and material that's been heat-damaged through aggressive grinding.

Common Problems from Poor Grinding

Uneven draw comes from inconsistent particles creating density variations and uneven airflow channels. One side consumes faster due to looser packing or the presence of concentrated fine particles. Customers complain about harshness and wasted material.

Harshness often comes from overly fine dust with excessive surface area that burns too hot and too fast, creating an unpleasant experience.

Loose packing happens when particles are too large. Material doesn't settle properly. Cones feel light and perform poorly. Proper grinding creates the foundation, but learning how to roll even cones completes the process.

Hand Grinding for Small-Batch Production

Manual grinding works fine in specific situations. Know when it makes sense and when you're just being stubborn about upgrading.

When Manual Methods Still Work

Personal use with under 20 cones daily doesn't justify equipment investment in industrial grinding systems. You're grinding for yourself, without the demands of commercial production. Speed doesn't matter much when production volume remains minimal.

Craft production and specialty batches benefit from hands-on control. Testing new varieties before scaled production makes sense with manual approaches where batch sizes stay small.

Cost considerations matter for starting operations. You need to prove the market before spending on equipment.

Basic Personal Grinder Types

Two-piece grinders offer simplicity. The three-piece adds collection chambers. The four-piece includes additional screening. For cone filling, consistency matters more than collection.

The capacity of basic personal grinders runs 1 to 3 grams per grind. Enough material for approximately 2-6 standard pre-rolled cones, depending on cone size. You're doing multiple grinds for even small cone batches.

Materials include aluminum alloy, stainless steel, and plastic. Aluminum dominates the market due to the cost-performance balance. Stainless steel lasts longer but is more expensive. Plastic works for extremely light use only.

Price ranges fall between budget-friendly and premium options, depending on quality and durability. You get what you pay for in terms of consistency and longevity. Check current pricing with manufacturers, as costs vary.

Manual Grinding Technique

Proper flower moisture content facilitates easier grinding and yields a more consistent particle size. Too dry and it turns to dust. Too moist, and it clumps in the grinder teeth.

Avoid over-grinding to a fine dust, which reduces cone airflow and draw quality. Stop checking mid-grind to prevent material loss. Grind for controlled rotations, then check particle consistency.

More isn't better, as excessive grinding generates heat and creates undesirable fine particles.

Consistent turning rhythm helps maintain particle uniformity. Rushing creates inconsistent results.

Check particle size before filling cones. Pinch test between fingers. Feel for chunks or excessive powder.

Efficiency Reality Check

Time investment with manual hand grinders averages 10 to 15 minutes per 20 cones, including multiple batches and setup. Scale that to 100 cones and you're looking at a serious time investment.

Physical effort for larger volumes creates real problems. Hand cramping from repetitive twisting motions. Wrist fatigue from sustained gripping pressure. Repetitive stress injuries happen with sustained manual grinding operations.

Consistency challenges across multiple grinds compound as volume increases. The first batch differs from the fifth batch. Fatigue affects technique. Compounding these issues, many operators unknowingly commit common cone roller mistakes that amplify the effects of inconsistent grinding on final product quality.

Manual methods become bottlenecks at around 50 to 100 cones per day. You're spending hours grinding when you should be doing other work.

Signs you need to upgrade include regular hand pain, inability to meet demand, and quality complaints from customers.

Premium Personal Grinder Options

Better personal grinders exist at higher price points. Sometimes they're worth it for the quality improvements achieved through better engineering.

Threadless Designs

Threadless operation using magnetic closure systems significantly speeds up the cone prep workflow. No screwing and unscrewing between grinds. Just pull apart and dump.

Aerospace aluminum is durable enough to withstand repeated use without degrading. These grinders last for years under regular operation.

Magnetic closure provides convenience without sacrificing seal quality. Quick to open. Stays closed during grinding.

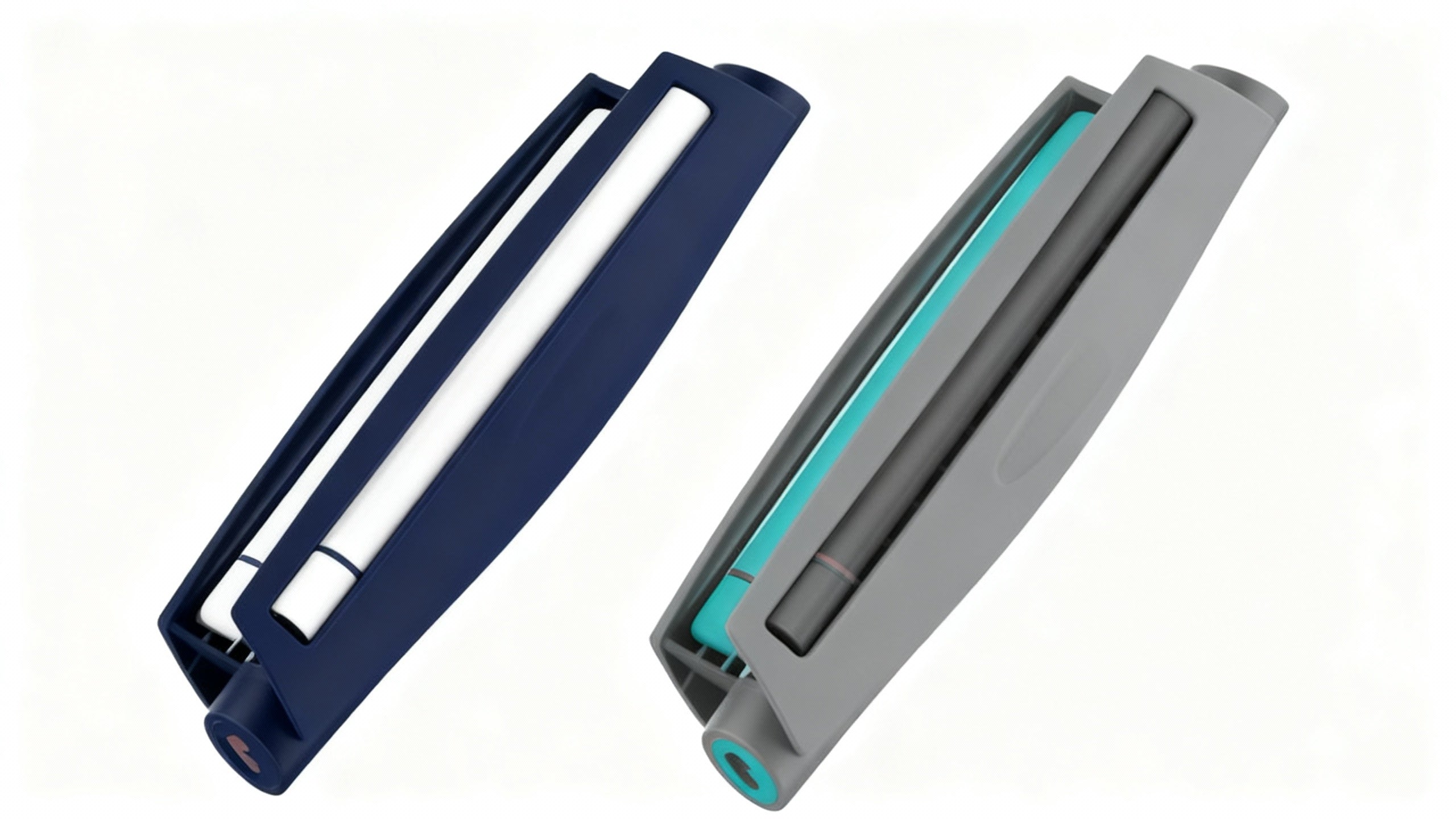

Grind plate options include fine, medium, and coarse settings. Switch plates based on which cone types you're filling. Standard cones want a medium grind. Slender cones prefer fine particles.

Investment runs in the premium category. The consistency improvement might justify the cost for serious cone packers producing moderate volumes on a regular basis.

Specialty Grinding Technologies

Some grinders use unique tooth designs that produce different particle structures. The material emerges fluffy with a preserved structure, rather than being compressed into dense clumps or powdery dust.

A fluffy grind prevents over-packing in cones by limiting the maximum density that can be achieved. Material settles naturally under gravity and vibration without excessive compression that restricts airflow.

Other grinders use milling versus grinding approaches. Plates shred material without the crushing action of traditional teeth, resulting in less friction and lower heat generation.

Electric Grinder Convenience

Automated electric grinding systems remove physical effort from the equation. Load the flower, press the button, and retrieve the ground material with a consistent particle size output.

Speed advantages matter for moderate cone production. You're preparing material faster than manual grinding without the physical fatigue from repetitive hand motions.

Battery life and portability considerations vary by model. Some need frequent charging. Others last days of regular use.

The price premium for automation represents an increased cost over basic manual grinders. You're paying for convenience and consistency improvements over manual grinding methods.

Electric makes sense for cone packers producing moderate daily volumes. Below that threshold, and manual works fine. Above that, industrial makes more sense.

Matching Grind to Cone Size

Different cone diameters need different particle sizes. This seems obvious, but most operations ignore it completely.

Standard Cone Requirements

Medium-fine particle size works best for standard diameter cones. Material flows through the cone body without excessive resistance. Packs evenly, achieving consistent density without creating air pockets.

Proper flow through the standard cone diameter requires particles that settle under vibration but don't compress into solid masses.

Avoid overpacking with too-fine a grind. Powder compresses too tightly. Airflow suffers. Channeling and draw instability become problematic.

Moisture content for packing standard cones should fall within a moderate range. Test with your specific material and adjust based on packing performance.

Slender Cone Considerations

A slightly finer grind is helpful for cones with narrower diameters. The restricted space requires smaller particles to flow through narrow cavities without excessive density, which would limit airflow.

Preventing gaps in slim cone packing requires uniform particle size. Inconsistency is more noticeable in narrow cones than in standard sizes.

Material flow challenges increase with the use of larger particles in slender cone applications. They bridge across the opening, creating air gaps rather than falling through smoothly.

Adjust grinder settings when producing slender cones regularly. Document what works for repeatability across production batches to ensure consistency and reliability.

Large Format Cone Needs

Larger cones accept slightly coarser grind without problems. The wider diameter provides more space for material settling during filling operations.

Prevent overly dense packing by using a coarser grind than you'd use for standard cones. Too fine and large cones become too tight, affecting airflow.

Airflow maintenance in larger diameters requires particles that create natural space between material fragments for proper performance. Medium grind works best for balancing packing density with airflow preservation.

Balance density with performance quality by testing different grinds. Too loose wastes material. Too tight performs poorly.

Industrial Grinding Solutions

Serious volume demands industrial equipment. Personal grinders can't handle the workload without breaking or driving you crazy.

When Industrial Equipment Makes Sense

Production volume thresholds requiring industrial grinding equipment typically reach around 500 cones per day. Below that level, semi-automated or premium personal grinders are effective. Above that volume, you need industrial capacity.

Cost-benefit analysis of industrial investment requires honest math. Calculate time spent grinding manually. Multiply by labor cost. Factor in quality issues from inconsistency.

Labor cost reduction through automation often justifies equipment investment within reasonable timeframes at high volume. One person monitoring industrial equipment replaces multiple people hand-grinding.

Quality consistency at scale becomes impossible without proper equipment. Fatigue affects manual grinding. Industrial equipment doesn't get tired.

Facility and electrical requirements include dedicated circuits and proper workspace. Industrial grinders pull serious power. Plan electrical upgrades before equipment arrives.

Industrial System Features

Industrial-grade pre-roll manufacturing equipment focuses on precision and consistency. Purpose-built equipment outperforms adapted solutions.

Precision grinding results in less waste through improved particle control. You're preserving more usable material per pound processed through reduced dust waste.

Low-speed high-torque systems maintain compound integrity. High-speed blenders can compromise quality due to the heat generated by blade friction.

Heat generation from friction in high-speed equipment is explained through basic physics. Blade speed creates molecular friction. Friction generates heat. Excess heat degrades volatile compounds.

Low RPM operation maintains compound integrity, preventing thermal degradation throughout grinding cycles.

Screen systems provide precise sizing for different applications. Swap screens for different cone types. Maintain consistency within each production run.

Selection Criteria

Match capacity to actual production needs based on daily cone output rather than aspirational volume. Oversized equipment sits idle, tying up capital unnecessarily.

Screen size options are crucial for operations that produce multiple cone types. Buy equipment that adapts to your product mix rather than single-purpose machines.

Stainless steel construction costs more but lasts longer in production environments. Aluminum works well but shows wear more quickly under constant use.

Cleaning and maintenance requirements affect total ownership cost. Some designs clean easily. Others require an extensive breakdown. Factor this into selection decisions.

Parts availability and warranty coverage determine downtime costs. Equipment breaks. Fast parts shipping and good warranty support minimize production interruptions.

Investment ranges for industrial flower grinding equipment vary considerably based on capacity and features. Verify current pricing directly with manufacturers as costs change.

Material Handling After Grinding

The time between grinding and filling significantly affects the final product quality, more than most operations realize.

Moisture Management

The proper moisture range for cone packing falls within moderate levels. Too dry creates harshness and dusty material. Excessive moisture can cause clumping in equipment.

Test moisture before grinding by feel and weight. Material should bend without crumbling or feeling damp to the touch.

Environmental storage considerations include humidity control. The material absorbs or loses moisture based on the ambient conditions in your workspace.

Storage Best Practices

Airtight containers prevent terpene loss through evaporation and oxidation exposure. Volatile compounds escape rapidly from ground material exposed to air.

Prevent moisture changes before filling through proper sealing. Ground material responds quickly to shifts in environmental humidity, affecting its packing characteristics.

Label ground material by variety and grind date. Inventory management prevents material aging in storage containers.

The maximum storage time before noticeable quality loss is approximately three to five days under proper conditions. Fill cones with ground material as soon as possible to preserve maximum quality.

Temperature and humidity control matter increasingly as storage time extends. Cool temperatures. Moderate humidity. Stable conditions throughout storage.

Batch Management

Grind quantities that match filling capacity within your quality window. Don't grind more than you can fill in a few days maximum.

Prevent material degradation from over-storage by managing batch sizes appropriately. Smaller batches are often superior to large batches sitting in storage, which tend to lose quality over time.

The workflow timing between grinding and packing should minimize delays. Grind today, fill today or tomorrow. Don't grind Monday for Friday filling operations.

Variety Considerations

Dense varieties grind differently from fluffy varieties. Some need less grinding time. Others require more work to break down properly.

Sticky flower handling techniques include chilling before grinding. Cold makes resinous material easier to process without excessive gumming in the grinder teeth.

Dry flower modifications might include moisture restoration before grinding. Very dry material becomes powder too easily, creating undesirable fine particles.

Document findings for repeatability. Next time you process the same variety, you'll know exactly what works based on previous results.

Optimizing Your Grinding Investment

Your grinder selection for flower pre-roll manufacturing directly determines the success of cone packing. Particle consistency is crucial for maintaining even material flow and ensuring predictable performance of filling equipment.

Hand grinders work for under 20 daily cones. Premium personal grinders are suitable for 20 to 100 daily servings. Semi-industrial options handle 100 to 500 cones. Industrial systems, such as those from Futurola, serve operations that exceed 500 daily cones.

Match grinder capacity to realistic production volume. Overbuying wastes capital. Underbuying creates bottlenecks.

Prioritize designs that minimize heat generation to preserve quality. Excess heat degrades terpenes. Aggressive grinding creates powder.

Plan how grinding is connected to your cone filling equipment. Grinding that produces the wrong particle size for your filling system wastes money on both ends.

Measure your current and projected daily cone production accurately. Use actual data, not hopes. Add a reasonable buffer for peaks.

Calculate the time and labor costs of your current grinding method. Multiply hours by wage rates. Factor in quality issues and customer complaints due to inconsistent particle sizes.

Research grinders appropriate for your volume tier. Don't jump to industrial if you're filling 50 cones daily. Don't limp along with hand grinding when you're filling 500 daily.

Consider complete system solutions from manufacturers like Futurola for industrial applications. As a leading pre-roll equipment supplier, Futurola designs grinders and filling systems to work together, ensuring particle consistency matches your specific cone packing requirements for optimal performance.

Verify current specifications and prices with manufacturers. Equipment changes. Prices fluctuate. Capabilities improve. Get current information before committing capital to equipment purchases.

Test different grind consistencies with your specific cone types. Standard cones versus slender cones need different approaches. Document what works for future reference.

Calculate returns based on labor savings and quality improvements. Generic calculations mislead. Do your own math with your own numbers reflecting actual costs.

Plan facility modifications for upgraded equipment before making a purchase. Electrical upgrades take time. Workspace reconfiguration requires planning and may necessitate permits.

Begin with the appropriate tier and plan your scaling path accordingly. It is better to upgrade twice than to overbuy once and tie up unnecessary capital in unused capacity.

Disclaimer: This analysis is for informational purposes only and should not be considered equipment purchasing or business advice. Grinder prices, capabilities, and specifications are subject to frequent change. Always consult current manufacturers for up-to-date information. Individual grinding and cone packing results vary based on flower quality, moisture content, material characteristics, and operator technique.

LEAVE A COMMENT

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.