Every user faces this fundamental choice: pre-rolled cones promise instant convenience and consistent results, while rolling papers offer complete control and traditional craftsmanship. Your choice affects product quality, long-term costs, skill development, and lifestyle compatibility.

Busy professionals might prioritize speed and consistency, while enthusiasts prefer the ritual and customization of hand-rolling.

Pre-rolled cones eliminate rolling skills while ensuring consistent construction and performance, but rolling papers provide infinite customization and often superior results when properly executed. This comprehensive analysis examines cost efficiency, quality differences, skill requirements, and practical applications to help you make the optimal choice for your needs.

Understanding the Basics: What Makes Each Option Unique

These two approaches represent fundamentally different philosophies toward preparation. Understanding their unique characteristics reveals why passionate advocates exist for both methods.

What Are Rolling Papers?

Rolling papers embody centuries of tradition, providing thin sheets of processed plant fibers that give users total control over construction, determining exact dimensions, density, and shape while creating a meditative ritual many consider integral to the experience.

Paper varieties offer extensive customization: ultra-thin rice papers provide minimal flavor interference, hemp papers offer extended performance and natural characteristics, flavored options add aromatics, and size ranges accommodate single-serving to party-sized creations.

Rolling papers represent the purist's choice for those valuing tradition, control, and the therapeutic aspects of manual preparation, remaining the gold standard for users who view construction as an art form.

What Are Pre-Rolled Cones?

Pre-rolled cones represent modern innovation designed to democratize preparation by eliminating skill barriers, arriving ready for filling with integrated filter tips preventing spillage, cone shapes creating optimal performance dynamics, and manufacturing precision ensuring consistent results that exceed most manual rolling through superior construction characteristics and draw consistency.

The convenience proves transformative for busy professionals who appreciate instant preparation, social users who avoid poor rolling techniques, and individuals who benefit from consistent construction and reliable performance.

Now that you understand both approaches, let's examine each option in detail to help you make the right choice for your needs.

Rolling Papers: The Traditional Choice

Traditional rolling papers represent the craftsperson's approach to preparation. These simple sheets unlock unlimited creative potential while maintaining the authentic, hands-on experience that connects users to centuries of culture.

Complete Control and Customization

Rolling papers provide unmatched control over construction, enabling users to create precisely tailored experiences from pencil-thin rolls for discreet consumption to large party rolls for group sessions.

Material distribution becomes an art form through consistent density control, intentional variations for optimal performance, and complete shape customization from cones to specialty forms with flexible filter integration.

The learning process itself provides satisfaction for enthusiasts, as they develop rolling skills, create personal achievements, and gain social credibility. At the same time, each successful roll represents a mastery progression, encouraging continued practice and refinement of technique.

Material Variety and Options

Rolling paper materials offer extensive choices that affect taste, performance characteristics, sustainability, and the overall experience.

Hemp papers represent the sustainable choice, providing extended performance duration and mild natural flavors while requiring minimal pesticides. Rice papers offer an ultra-thin construction for purists seeking minimal interference with superior taste profiles, but require careful handling. Wood pulp papers, on the other hand, provide traditional experiences at accessible prices with reliable performance suitable for various skill levels.

Flavored options add aromatic elements through fruit, mint, or dessert infusions, appealing to users seeking variety or wanting to enhance flavor profiles for social situations. However, purists often avoid them, believing they compromise authentic taste experiences.

Size and Shape Versatility

Rolling papers cater to diverse consumption needs through their extensive size ranges.

Single-wide papers (70mm) provide classic proportions for personal consumption, holding 0.5-0.7 grams, regular 1¼ size papers (78mm) offer the most popular choice with optimal balance between capacity and construction ease, and king-size papers (100mm+) create generous rolls holding 1.5-2.5 grams, suitable for parties or extended sessions requiring moderate skill levels.

Size selection significantly affects session duration, with larger papers creating longer-lasting products, while smaller options are better suited for quick sessions or users who prefer frequent, smaller doses.

Economic Advantages

Rolling papers deliver exceptional value through high quantity packaging (32-50 sheets) with minimal per-unit costs ($0.05-0.15 per sheet versus $0.50-1.50 for pre-rolled cones), with regular users consuming one roll daily, spending approximately $36.50 yearly on papers versus $365 annually for equivalent pre-rolled cones, a tenfold cost increase.

Economic benefits extend beyond simple paper costs through reduced waste, customization flexibility, and precise portion control, enabling smaller rolls during tolerance adjustments or larger ones for special occasions.

Challenges and Drawbacks of Rolling Papers

Traditional rolling demands honesty about its limitations. While purists celebrate the craft, practical challenges discourage many potential users from developing rolling skills.

Skill Requirements and Learning Curve

Hand-rolling requires fine motor control and dexterity that proves challenging for individuals with arthritis, tremors, or limited finger mobility, with basic competency requiring 2-4 weeks of regular practice and consistent quality taking 2-3 months, while common beginner mistakes (overpacking, underpacking, uneven distribution) waste materials and create disappointing experiences.

Environmental factors (wind, humidity, cold weather, poor lighting) complicate learning processes. At the same time, social pressure during group sessions creates anxiety that hinders skill development when friends expect competent rolling during shared sessions.

Time Investment and Convenience Factors

Rolling requires significant time investment that many find impractical. Experienced rollers need 3-5 minutes per roll, while beginners require 10-15 minutes, including preparation and cleanup. Failed attempts often double or triple this investment.

Waste and Material Loss

Learning to roll inevitably creates material waste, affecting budgets and environmental consciousness, with beginners wasting 20-30% of papers due to tearing (delicate rice papers tear easily, excessive moisture weakens integrity), failed rolls creating complete material losses through loose construction or uneven packing, and herb spillage occurring frequently through handling mistakes and construction errors.

Beginners purchasing 1 gram of premium material at $15 might waste 30-40% during the initial learning phases, representing $4.50-$6.00 in lost material per practice session, with combined paper waste adding substantially to consumption budgets.

Pre-Rolled Cones: The Convenience Revolution

Pre-rolled cones represent a fundamental shift toward accessibility and reliability in preparation. These engineered solutions eliminate traditional barriers while delivering consistent results that satisfy both newcomers and experienced users seeking convenience.

Instant Perfection and Consistency

Pre-rolled cones guarantee perfect construction every time with optimal density distribution, precise dimensions, and professional-grade quality that most users cannot achieve manually.

This ensures identical proportions and construction standards through manufacturing quality control, unlike hand-rolled products that vary dramatically based on skill levels and environmental conditions.

The psychological benefits prove substantial for users tired of rolling disappointments. Guaranteed success reduces anxiety and frustration, providing quality predictability in performance characteristics through engineered airflow and density patterns. This significantly improves social confidence, enabling users to produce impressive results without prior personal rolling skills during group sessions.

Speed and Efficiency Benefits

Pre-rolled cones deliver dramatic time savings through streamlined fill-and-twist processes, with experienced users preparing quality products in under 60 seconds compared to 3-5 minutes for hand-rolling through simple material insertion, even distribution via gentle tapping, and tip closure.

Efficiency gains compound in social situations where multiple products require preparation (3-5 minutes total versus 15-20 minutes for hand-rolling), travel scenarios that benefit from rapid preparation without elaborate workspace arrangements, and professional settings that demand maximum efficiency for limited break times.

Beginner-Friendly Accessibility

Pre-rolled cones eliminate intimidation factors and complex motor skills that discourage experimentation. Success guarantees build confidence for newcomers, allowing them to focus on the experience rather than struggling with construction techniques during social situations.

Learning curves disappear entirely, enabling immediate participation in culture without extended practice periods.

Physical limitations become irrelevant for users with arthritis, tremors, or reduced dexterity who cannot develop traditional rolling skills. This ensures equal access to experiences regardless of physical capabilities.

Users can shift their focus from mechanical preparation to appreciation of consumption, strain characteristics, flavor profiles, and social interactions.

Built-in Quality Features

Pre-rolled cones incorporate professional-grade components that exceed typical hand-rolling standards, featuring integrated filter tips that prevent debris and optimize airflow using food-grade materials specifically designed for these applications. These are superior to improvised cardboard or paper filters.

Paper selection reflects the manufacturer's expertise in performance characteristics and flavor neutrality. Construction quality ensures consistent density and airflow through precision manufacturing equipment, controlling variables that are impossible to manage through hand-rolling.

Quality control processes verify each cone meets manufacturing standards before packaging. This eliminates defective products with tears, improper dimensions, or structural flaws that could waste materials or create disappointing sessions.

Unique Burning Characteristics

The tapered cone shape creates a distinctive performance progression, differing fundamentally from straight rolls, with wide openings enabling generous material capacity. At the same time, narrow tips provide controlled start and consistent draw resistance.

This creates a natural progression from concentrated initial draws toward mellower finishing draws as the diameter increases.

Airflow optimization occurs through the shape's natural venturi effect, where a narrowing diameter increases draw velocity while an expanding chamber allows proper mixing and cooling. This improves product quality compared to straight rolls.

The design naturally adjusts session pacing by changing draw resistance, encouraging mindful consumption. It improves material utilization by ensuring complete consumption to minimal remainders.

Limitations and Considerations of Pre-Rolled Cones

Despite their convenience advantages, pre-rolled cones present specific limitations that affect long-term value propositions and user flexibility. Understanding these constraints helps inform balanced purchasing decisions.

Higher Cost Per Unit

Pre-rolled cones command significant price premiums over rolling papers, with individual cones costing $0.50-1.50 versus papers at $0.05-0.15 per sheet, representing 300-1000% price differences.

Daily users spend $182.50-547.50 annually on cones compared to $18.25-54.75 for papers, creating substantial budget impacts for frequent consumers.

Manufacturing complexity justifies some premium pricing through precision equipment and quality control, though markups often exceed cost differences significantly.

A cost analysis must consider both the time value and waste reduction. Higher wages might justify premium pricing, while beginners avoid material waste through guaranteed success, potentially offsetting higher cone costs through reduced spillage.

Limited Customization Options

Pre-rolled cones restrict creativity through standardised dimensions and predetermined specifications, eliminating the infinite flexibility available with rolling papers.

Size constraints limit users to manufacturer options ranging from 0.5-gram mini cones to 1.5-gram king-size versions, inadequate for ultra-small personal doses or large party rolls.

Shape standardisation prevents experimentation with different profiles. Users cannot create straight rolls, unusual tapers, or novelty shapes that hand-rolling accommodates.

Density control remains fixed rather than adjustable for session preferences.

Filter options remain limited to manufacturer selections, without upgrade possibilities, which restricts personal filtration preferences from traditional experiences to elaborate cooling constructions.

Storage and Durability Concerns

Pre-rolled cones exhibit fragility requiring careful handling and protective storage to maintain structural integrity. Hollow construction makes them susceptible to crushing and deformation, compromising functionality.

The cone structure collapses easily under pressure from backpacks, pockets, or storage containers, making crushed cones difficult to fill correctly. Damaged tips prevent effective closure.

Storage requirements exceed those of flat rolling papers, requiring demanding, rigid protection via specialised containers to maintain shape integrity.

Transportation risks multiply during travel when luggage compression could damage stored cones.

Moisture sensitivity affects integrity by weakening the paper. Humid environments cause limpness, while dry conditions create brittleness, requiring climate control exceeding rolling paper requirements.

Making Your Personal Choice Based on Your Lifestyle

The choice between pre-rolled cones and rolling papers ultimately depends on your unique circumstances and priorities. Neither option proves universally superior, but one will align better with your specific needs and preferences.

Assess Your Priorities

Consider your current skill level honestly. Beginners benefit from cone reliability while experienced rollers might prefer traditional craftsmanship.

Budget consciousness influences long-term satisfaction. Regular users save substantially with papers despite learning investments, while occasional users might find cone premiums acceptable for guaranteed convenience.

Consider Your Usage Patterns

Lifestyle compatibility determines practical suitability. Social users need reliable group preparation, while leisure users might appreciate rolling rituals.

Time availability affects practical choices. Rushed schedules favor instant cone preparation, while relaxed environments allow manual rolling's meditative qualities.

Find Your Balance

Experimentation provides the clearest path toward optimal choices. Try both approaches across different situations to understand personal preferences.

Many users adopt hybrid approaches, using cones for convenience situations while hand-rolling when time permits. This flexibility maximizes both approaches' advantages while minimizing their limitations.

Making Your Personal Choice

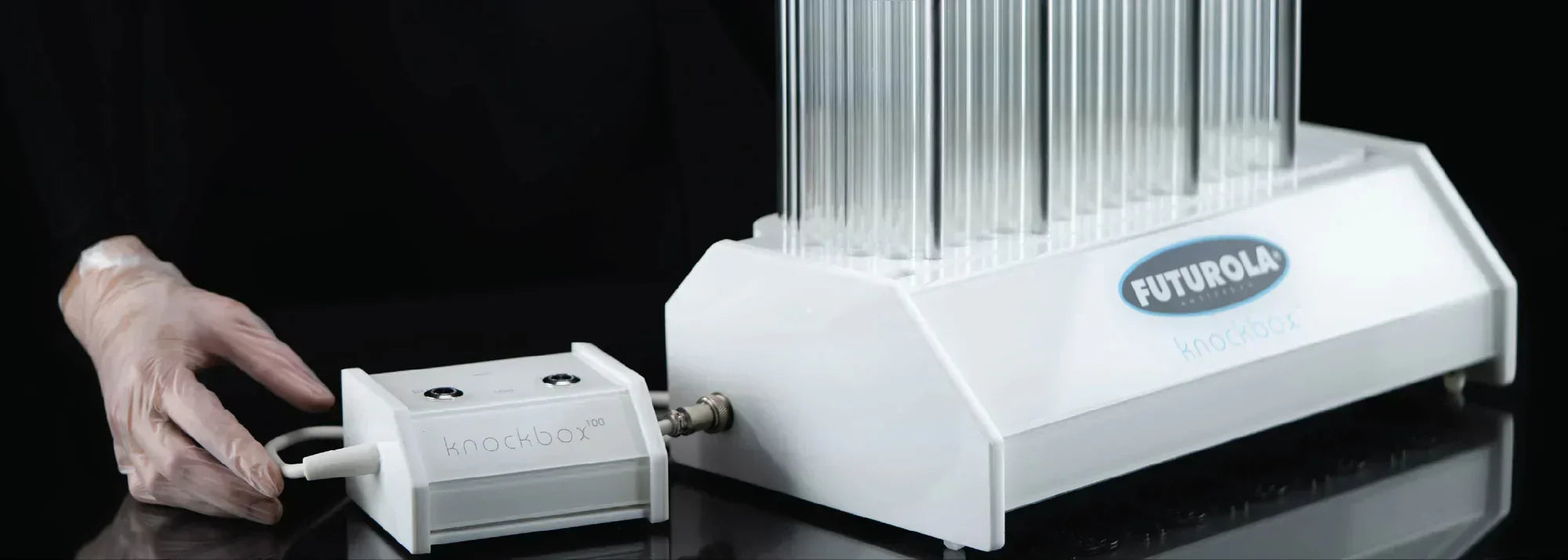

The choice between pre-rolled cones and rolling papers ultimately depends on your unique circumstances and priorities. Neither option proves universally superior, but one will align better with your specific needs and preferences. At Futurola, both product categories receive equal attention to quality and innovation, recognizing that different consumers have different requirements.

Consider your current skill level honestly. Beginners benefit from cone reliability while experienced rollers might prefer traditional craftsmanship. Budget consciousness influences long-term satisfaction; regular users save substantially with papers despite learning investments, while occasional users might find cone premiums acceptable for guaranteed convenience.

Lifestyle compatibility determines practical suitability. Social users need reliable group preparation. Busy professionals favour quick preparation, while leisure users might appreciate rolling rituals.

Experimentation provides the most straightforward path toward optimal choices. Try both approaches across different situations to understand personal preferences. Your choice reflects personal priorities rather than objective superiority; therefore, make informed decisions based on an honest self-assessment rather than external pressures.

LEAVE A COMMENT

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.