The pre-roll revolution has transformed the industry, reaching 15.4% market share by June 2024 with over $4.1 billion in sales across tracked markets. This explosive growth demands efficient production systems that scale with demand while maintaining quality standards.

Manual rolling cannot compete with market velocity, as consumer expectations shift toward consistently constructed, professionally produced products available on demand. Dispensaries require reliable inventory that performs consistently and delivers predictable experiences.

Modern pre-roll machines bridge this gap through precision engineering and automated efficiency, evolving from simple cone-filling devices to comprehensive production solutions. These systems produce thousands of units daily, ranging from entry-level semi-automated systems to fully integrated production lines.

This guide examines every critical factor affecting machine selection, exploring equipment categories from tabletop units to industrial systems. We analyze feature sets for different business scales and provide practical frameworks for calculating return on investment.

Understanding Pre-Roll Machines

Pre-roll machines are automated devices designed to streamline the production of joints from raw flower to finished products, handling multiple stages (grinding, sifting, filling, tamping, and closure) while maintaining consistent quality standards that are impossible to achieve through manual methods.

These systems solve industry challenges of rising labor costs, skilled worker scarcity, and quality inconsistency through precision automation and standardized processes.

These systems ensure consistent tamping pressure for even density, controlled filling weights for regulatory compliance and material optimization, and automated closure techniques preventing structural failures.

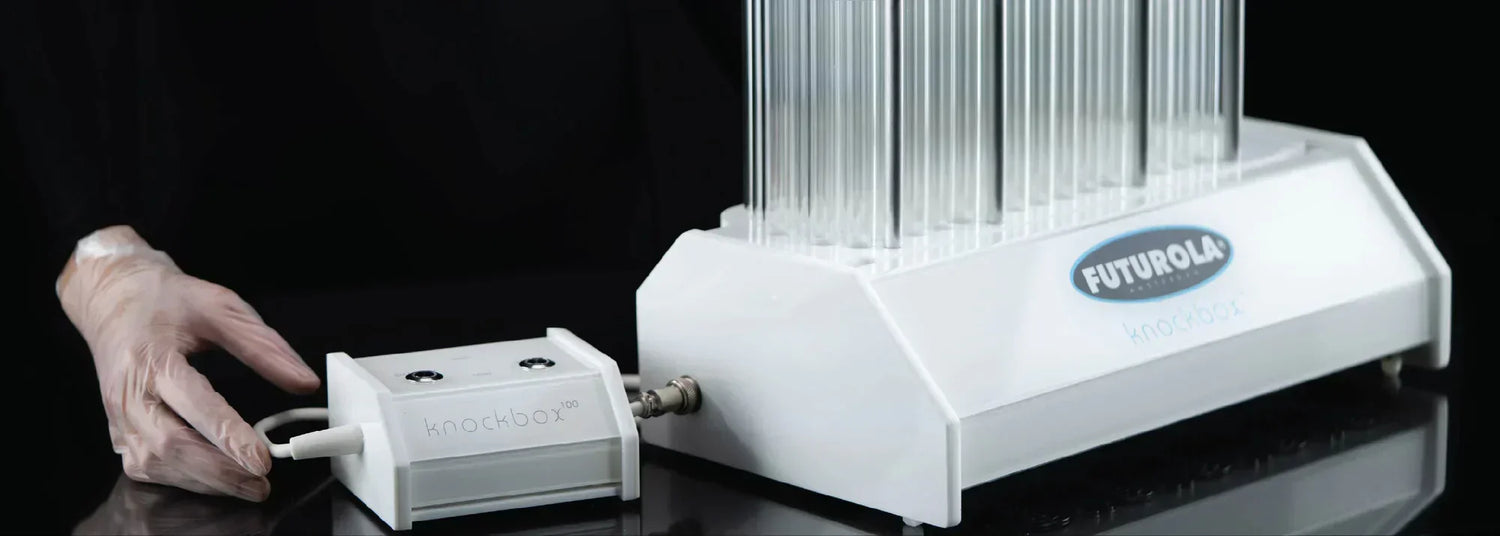

They accommodate various production scales, ranging from small-batch artisanal operations using semi-automated systems, such as the Knockbox series, to high-volume commercial facilities with fully automated, integrated production lines.

Market Impact and Growth Statistics

The pre-roll market expansion underscores the critical importance of production automation, with its market share increasing from 13.2% in January 2023 to 15.4% by June 2024.

Sales volume exceeded 394 million units across thirteen tracked states, generating revenue of over $4.1 billion.

Growth projections indicate continued expansion driven by shifts in consumer preferences toward convenience products, regulatory standardization that reduces market barriers and enables interstate commerce, and product innovation, including infused options and premium materials, which attract higher-value customers.

Types of Pre-Roll Machines: Complete Classification

Understanding machine categories enables informed selection decisions based on production requirements, investment capacity, and growth projections. Each classification serves specific operational needs with distinct advantages and limitations.

Manual and Semi-Manual Systems

Entry-level machines bridge the gap between hand-rolling and automation, providing cost-effective solutions for small operations. Key types include knockbox systems (vibration and manual tamping, 50-500 units per batch), bump boxes (basic vibration with minimal investment but labor intensity), and manual cone fillers (hand-operated devices improving consistency over hand-rolling). These systems require significant operator involvement but deliver improvements in consistency, with training periods of 1-2 weeks for proper flower preparation, packing density recognition, and technique development.

Semi-Automatic Pre-Roll Machines

Mid-level automation strikes a balance between production efficiency and operator involvement. Primary systems include vibration-based machines (with adjustable intensity and timer controls), batch processors (capable of processing 20-100 cones simultaneously), and electronic tamping systems (ensuring consistent pressure with programmable sequences for optimal performance).

Production ranges from 1,000 to 5,000 units per shift, with investment considerations including equipment costs ($15,000-$75,000), training, maintenance, and potential facility modifications.

Fully Automatic Pre-Roll Machines

Enterprise-level systems minimize human intervention while maximizing consistency and throughput. Features include continuous-flow processing (integrated stages from grinding to finished products), complete production lines (encompassing grinding, moisture control, filling, inspection, and packaging), and minimal-intervention operation (with operators primarily responsible for loading and monitoring).

Production typically exceeds 3,000 to 10,000 units per shift, with high-end installations achieving 15,000+ units.

Requirements include substantial floor space, electrical infrastructure, compressed air systems, and investments of $200,000 to $ 800,000.

Specialized Machine Categories

Specialized equipment addresses unique production requirements and emerging market segments. Key categories include infusion machines (incorporating concentrates for "hash hole" effects), coating systems (automated application of oils and enhancements), packaging integration (production combined with immediate packaging and labeling), and custom application machines (oversized products, unusual shapes, specialized materials).

These systems enable product differentiation and premium market positioning beyond standard machine capabilities.

Pre-Roll Construction Methods and Technologies

Understanding construction methodologies enables informed equipment selection based on quality requirements, production goals, and target market positioning. Different approaches create fundamentally different products with distinct characteristics.

Cone Filling vs. True Rolling Systems

The construction method fundamentally determines product quality and performance characteristics. Cone filling systems, which use pre-manufactured cones packed through tamping or vibration techniques, offer limited customization and often result in uneven density distribution, characterized by compressed bottoms and loose tops that cause inconsistent performance.

True rolling systems construct joints from flat papers using hand-rolling techniques that control every aspect of formation, resulting in seamless construction and even density distribution, which in turn yields superior performance characteristics.

Production considerations include cone filling and achieving higher throughput through simplified operations that require minimal expertise, versus rolling systems operating at slower speeds due to construction complexity, which deliver superior product quality that commands premium pricing.

Tamping and Compaction Technologies

Compaction methods directly affect product density, burning characteristics, and quality through vibration tamping (controlled oscillation with variable frequency settings preserving trichome integrity), piston compression (direct mechanical pressure with programmable settings for precise density control), radial compaction (circumferential pressure application mirroring hand-rolling techniques for even compression), and centrifugal filling (rotational force through controlled spinning for consistent density with gentle material handling).

The quality impact varies significantly between methods, with gentle techniques preserving trichome integrity and natural flower structure, while aggressive compression methods can affect potency and disrupt airflow patterns.

Key Features and Selection Criteria for Pre-Roll Machines

Selecting optimal equipment requires a systematic evaluation of features that directly impact business success. Understanding these criteria enables informed decisions aligning with operational goals and market positioning.

Production Speed and Capacity Analysis

Production capabilities determine market reach and revenue potential. Entry-level manual systems produce 200-500 units per eight-hour shift (knockbox systems achieve 800-1,500 units with experienced operators), semi-automatic systems deliver 1,000-3,000 units per shift through reduced operator fatigue, and fully automatic systems excel with 5,000+ units per shift (advanced installations achieving 10,000-15,000 units daily).

Scalability factors include machine modularity and expansion capabilities, which accommodate growth without requiring complete equipment replacement.

Multiple smaller machines often provide better flexibility through parallel operation and reduced downtime risks, while production optimization requires understanding material preparation quality and contamination control factors.

Precision and Consistency Requirements

Accuracy specifications have a direct impact on regulatory compliance, customer satisfaction, and operational efficiency. Advanced machines achieve weight consistency of ±0.01 grams through precise metering and electronic scales with automatic rejection, density uniformity of less than 5% variations through controlled pressure application, and dimensional tolerances of within 1-2mm for length and 0.5mm for diameter.

Quality control features include real-time monitoring systems that track production variables and identify deviations before defective products reach the packaging stage, with statistical process control enabling trend analysis and predictive adjustments across thousands of units.

Ease of Use and Operator Requirements

User interface design has a significant impact on production efficiency and operator satisfaction. Training requirements vary from 1 to 2 weeks for manual systems to 3 to 5 days for automated systems, plus technical maintenance training.

Skill levels range from a basic understanding of mechanical principles for simple machines to technical expertise and computer literacy for advanced automated systems. Interface complexity affects daily efficiency.

Touchscreen controls offer intuitive operation, while traditional switches provide reliability in harsh environments. Labor considerations include staffing requirements, with manual systems needing dedicated operators versus automated machines requiring periodic attention, allowing operators to handle multiple systems simultaneously.

Durability and Build Quality

Construction materials directly affect equipment lifespan and maintenance requirements. Quality machines operate continuously for 5-10 years, whereas budget alternatives typically require replacement within 2-3 years.

Material choices include stainless steel construction (excellent corrosion resistance and easy cleaning), aluminum (weight reduction with adequate durability), and food-grade materials (ensuring product safety and regulatory compliance).

Maintenance requirements include regular cleaning, lubrication, and replacement of components. Well-designed machines minimize complexity and identify wear components (such as seals, bearings, and cutting elements) for proper spare parts inventory and replacement scheduling.

Investment Analysis and ROI Considerations for Pre-Roll Machines

Understanding financial implications enables informed equipment decisions that align with business objectives and cash flow capabilities. Proper analysis prevents under-investment that constrains growth while avoiding over-investment that strains resources unnecessarily.

Cost Analysis: Machine Categories and Pricing

Equipment investment requirements vary dramatically across categories, with entry-level systems ($10,000-$50,000) including manual and semi-automatic equipment, such as the Knockbox series, which is suitable for craft producers and market testing.

Mid-range automation systems ($50,000-$200,000) deliver substantial production increases for growing operations, while enterprise solutions exceed $200,000. Fully automatic systems range from $250,000 to $500,000, and premium installations exceed $800,000 for comprehensive automation.

Total cost of ownership includes installation (adding 10-25% depending on complexity), training expenses ($2,000-$10,000), and maintenance costs (5-10% of equipment value annually) beyond initial equipment purchase.

This requires accurate budgeting and realistic financial planning for sustainable growth.

ROI Calculation and Payback Analysis

Return on investment analysis enables objective equipment evaluation through quantifiable benefits, including labor savings (the most significant component with manual operations requiring 2-4 operators producing 500-1000 units per shift versus automated systems achieving 3000-5000 units with single operator supervision for annual savings of $100,000-300,000).

Additional benefits include production efficiency gains (15-25% waste reduction through precise material control), and quality improvements enabling 10-20% price premiums through enhanced consistency while reducing returns and complaints.

The payback period calculation divides the total investment by the annual benefits, with typical periods ranging from 12 to 36 months, depending on production volumes and labor cost savings.

Understanding Business Readiness and Implementation

Successful automation requires careful timing and thorough preparation to maximize investment returns while minimizing operational disruption. Understanding readiness indicators prevents premature investment while identifying optimal implementation windows.

Determining When to Automate

Automation timing significantly impacts investment success. Production volume thresholds provide clear triggers for when to invest.

Operations consistently producing 500+ units daily experience labor bottlenecks. Businesses projecting 1000+ daily should plan implementation.

Current production analysis indicates that automation benefits when spending 8+ hours daily on pre-roll production. Quality rejection rates of 10% or higher also indicate a need for automation.

Labor cost analysis justifies wage escalation and the scarcity of skilled workers. Hourly wages of $ 20 or more accelerate payback periods, while skilled roller scarcity limits scalability.

Quality consistency requirements often drive automation, independent of volume. Medical markets demand precise dosing and regulatory compliance, requiring quality documentation.

Financial readiness includes maintaining 6-12 months of operating expenses in reserve. Equipment financing should be secured without constraining operational flexibility.

Facility Requirements and Setup

Proper facility preparation ensures optimal equipment performance and efficient workflows. Space requirements vary dramatically across equipment categories.

Entry-level equipment requires 50-100 square feet of space. Mid-range systems require 200-400 square feet, while enterprise installations require 1,000 square feet or more.

Power specifications range from standard 220V single-phase for basic systems to 480V three-phase for automated lines. Electrical upgrades can cost between $10,000 and $ 50,000.

Compressed air systems require 20-100 CFM at 90-120 PSI with filtration and moisture removal. These systems are essential for pneumatic operations.

Environmental controls maintain optimal temperature (18-24°C) and humidity (45-55%) conditions. These factors directly affect equipment performance and product quality.

Workflow optimization requires careful equipment placement and material handling design. Linear production flows reduce bottlenecks, while circular layouts enable efficient material circulation with adequate workspace for maintenance access and operator safety.

Staff Training and Operational Changes

Workforce transition requires comprehensive training programs. Basic systems need 2-5 days, while complex automated lines require 1-2 weeks.

Training covers equipment operation, quality control procedures, and troubleshooting. Technical competencies include quality assessment, computer literacy for digital interfaces, and mechanical understanding for maintenance.

Operational procedure changes include revised workflows and quality control protocols. Documentation requirements support automated production with enhanced consistency through automated inspection and statistical process control.

Change management addresses employee concerns through effective communication programs. These emphasize skill development opportunities and job security through increased productivity.

Pre-Roll Machine Maintenance and Operational Tips

Proper maintenance ensures consistent performance while protecting equipment investments through extended service life and reduced downtime. Understanding maintenance requirements enables accurate operational budgeting and optimal equipment utilization.

Preventive Maintenance Programs

Systematic maintenance programs prevent costly failures while ensuring consistent production quality and equipment reliability. Proper maintenance protects your investment and maintains operational efficiency.

Daily procedures include thorough cleaning of product-contact surfaces using food-grade solvents. This addresses grinding chambers and filling mechanisms to prevent contamination and buildup.

Lubrication is performed according to manufacturer specifications using food-grade lubricants. Over-lubrication attracts contamination while under-lubrication accelerates wear.

Weekly tasks include a detailed inspection of wear components and verification of calibration. Belt tension adjustments and pneumatic system checks are also essential.

Component replacement schedules based on operating hours or production volumes prevent unexpected failures. Periodic replacement of wearing parts (seals, bearings, cutting elements) maintains reliability.

Maintenance costs typically range from 5% to 10% of the equipment's value annually, depending on usage intensity. Basic machines require minimal maintenance while complex automated systems demand comprehensive service programs.

Troubleshooting Common Issues

Understanding common problems and their solutions minimizes downtime, enabling operators to resolve minor issues efficiently. Systematic troubleshooting approaches prevent extended production interruptions.

Jamming represents the most frequent problem in pre-roll machines. It's caused by material characteristics, variations in moisture content, stems, or foreign objects, requiring specific cleaning protocols and material preparation procedures.

Inconsistent filling problems result from calibration drift or worn components. These issues require verification and inspection to restore proper operation.

Quality variations include density inconsistencies caused by worn tamping components or adjustment drift. Systematic monitoring and operator training address these problems.

Mechanical issues, such as unusual noises, vibration, or reduced performance, indicate developing problems. These require immediate attention to prevent major failures.

Prevention strategies include operator training, regular inspections, and proactive maintenance. Addressing problems before they affect production prevents catastrophic failures and maintains production continuity.

Making Your Pre-Roll Equipment Decision

Selecting the right pre-roll machine requires balancing your current production needs, budget constraints, and growth projections. At Futurola, the automatic cone filling machine revolutionized how the industry produces pre-rolled cones professionally and at bulk, setting new standards for efficiency and consistency. Whether you choose manual systems for craft operations, semi-automatic equipment for growing businesses, or fully automated lines for high-volume production, the key is matching technology capabilities with your operational requirements.

The pre-roll market's continued expansion presents significant opportunities for businesses equipped with appropriate production capabilities. Success depends on a thorough needs assessment, realistic ROI analysis, and proper implementation planning. Take time to evaluate your options, consult with equipment specialists, and visit operating installations before making your investment decision. This choice will shape your business trajectory for years to come.

LEAVE A COMMENT

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.