The industry’s growth has fuelled a lot of advancements in manufacturing pre-rolls at scale. Dispensaries and other vendors have been looking for ways to amp up production without increasing labor costs, especially given the tumultuous labor market today. There is an increasing reliance on machinery to do the job, and there are quite a few options on the market too.

However, perfecting a pre-roll is not easy. Getting the perfect blend of mix quality, texture, roll quality, and smoking experience can take years to develop. Doing it by hand is one way to ensure quality and consistency but the time it takes to produce a few joints will be too high to make it economically viable for you.

Investing in the right equipment and using it properly is often the answer to this. In this blog, we will shed some light on what makes a pre-roll top shelf quality and how to get there using Futurola’s top-of-the-line products that are designed for the perfect smoking experience. Read on!

What Makes a Pre-Roll Top-Shelf Quality?

Let’s begin here. The whole discussion about the quality of a pre-roll comes down to how good the smoking experience is. There are several aspects that matter when it comes to rolling a great reefer.

Quality of the Strain

Of course, this is a significant aspect in determining the overall quality of the joints. You need good quality material to produce a good top-shelf quality pre-roll. If you are using sub-standard strains, however, well you do the rest of the process, the quality is going to remain low. So the first thing to do is to perfect your mix. Experimenting with various strains and understanding which ones work best is the way to go.

The Consistency of the Mix

How fine the mix is has a lot to do with how good the smoking experience really is. You need to make sure that the mix isn’t ground too fine or it isn’t too coarse. A fine mix will result in an extremely dense pre-roll and the airflow will be limited. Using a mix that is too coarse will again result in the joint having too much space inside and would not be strong enough. Finding the right consistency is important for great quality.

The Rolling Paper Used

Not a big surprise that the rolling paper you use also has an impact on how good the joint turns out to be. There are a variety of materials and sizes of papers available today. Depending on the type of paper you use and the size, the joints will burn faster or slower. It also determines the taste and ease of rolling.

The Sturdiness of the Joint and Density of the Fill

Finally, the quality of the fill is an important criterion. You a joint that is just the right density and filled with the right quantity of mix to ensure a smooth smoking experience. If the density of the fill isn’t right, it can turn out to be quite difficult to smoke. Getting an even burn is another aspect that is impacted by the density of the roll. Getting it right is the difference between a good roll and a bad one.

For facilities that are mass producing this, it takes some time to perfect the art of pre-roll production. There is equipment available that can make this process easier. The next section will talk about how you can use the best equipment available to get the perfect pre-roll and keep your production capacity up at the same time.

Using the Right Machinery for the Job

Futurola’s state-of-the-art equipment is designed for pre-roll production at scale. Knockbox 3 is a popular pre-rolled cone filling machine that is a vital part of many production units today. But beyond this, there are other types of equipment that can help you with the task and automate the process as best as possible. Here’s how these types of equipment and products can help you achieve top grades in all the parameters discussed above.

Futurola Trimmers

Trimmers are essential to trim down full unbucked plant material into smaller sizes. It eliminates the need for manual intervention. Trimmers are great if you are working with large buds and plants that are unprocessed which is often the case. Doing it manually reduces the wastage as much as possible and gives you a clean product that can be processed further. However, the time and the costs of doing it manually can up your production costs a lot. There’s no guarantee that the final outcome will be consistent too.

Trimmers are designed to do this without impacting the quality of the material. You get a consistent trim every time using the Futurola trimmers. The trimmer pulls the leaf from the stem and the stalks are also trimmed and cleaned. The trimmer works at 16 rotations per minute which keeps the structure of the plant intact.

Trimmers can run in cycles of 1-15 minutes with an average cycle time that is commonly used varying between 2 and 7 minutes. Futurola trimmers are available in 3 sizes

- Mini- 2 pounds per load

- OG- 4 pounds per load

- Mega- 15 pounds per load.

Depending on the need and the capacity, you can purchase the trimmer that suits your need. The material that is trimmed can now be shredded in the next step.

Futurola Shredders

Shredders are designed to shred several pounds of material in one go and produce mixes that can work with roll cone filling machines in the next step. Futurola shredders evenly shred the trimmed product into a consistent mix. The shredder can be set using a timer that goes from 1-15 seconds. The average cycle time is from 2-7 seconds.

The shredder has a stainless steel tunnel with nylon whips that shreds the material. It also comes with a glass lid for safe operation. Using add-ons such as screen barrels allows you to separate stems from the mix and also clean the mix from large pieces that were left over from the shredding process. Shredders are available in many different capacities - Super mini, mini, OG, Super, Mega, and Super mega. The shredding capacity ranges from 0.7 pounds to 7 pounds per cycle.

Shredders are a critical component of the process in producing an even mix that can be filled into the paper cones later using pre-roll machines. It allows you to get the density of the mix right. Cone packer machines are also important but getting it wrong here can impact the overall quality of the pre-roll.

Selecting the Correct Rolling Papers and Cones

The next step is selecting the right rolling paper or pre-rolled cones to make your joints. It is important to use paper with the right thickness and made of the right material. Futurola’s rolling papers and pre-rolled cones are made of clean and tested paper that is designed for even burn and good taste.

Using the right size is also an essential criterion. King-sized cones give you larger joints but may not suit all joint rolling machines. There are other sizes of pre-roll tubes also available like slender and fat boy. Depending on the size of the joints you want to produce, use the right cone sizes.

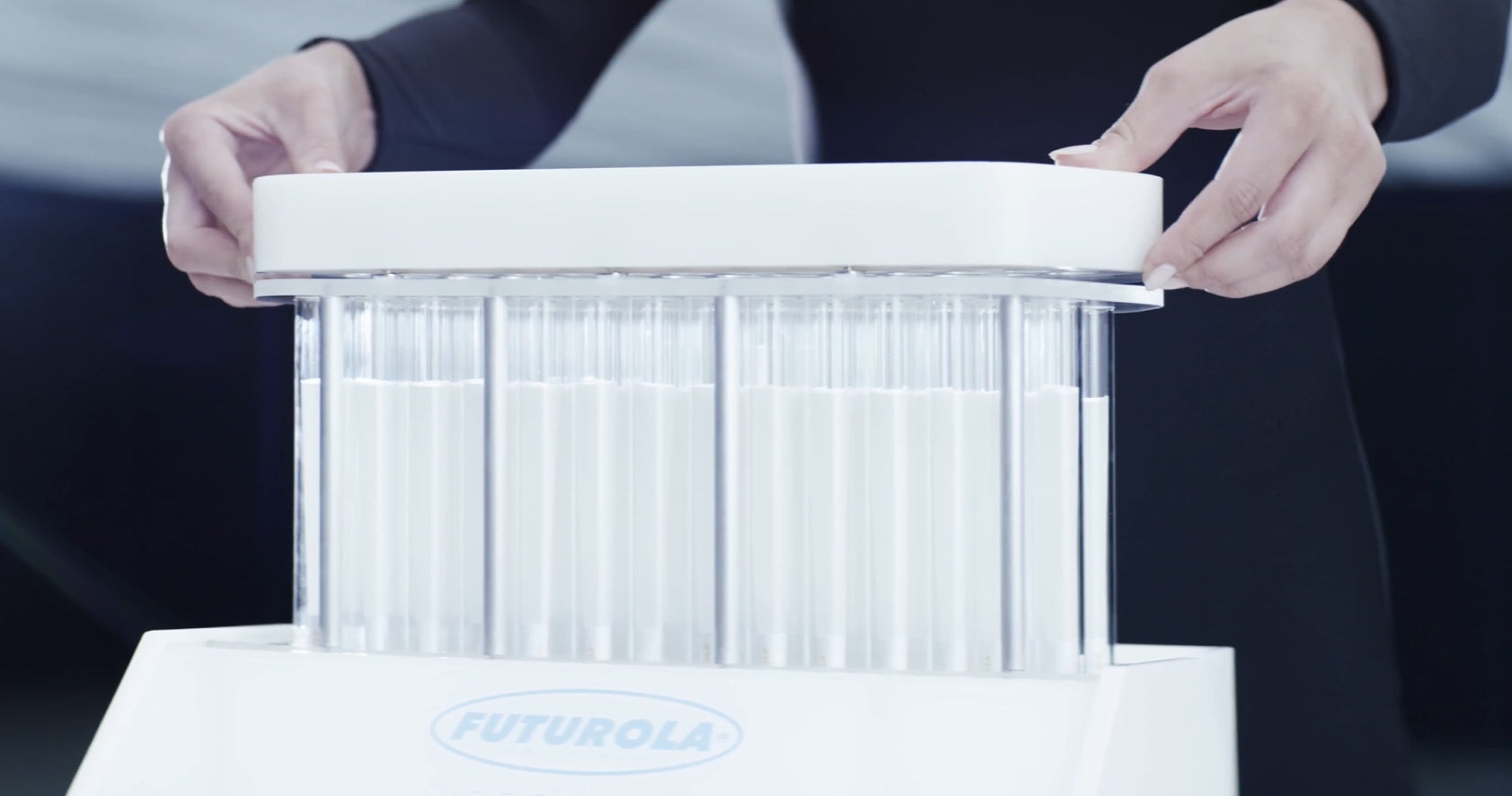

The Cone Filler Machine- Futurola Knockbox

The final piece in the puzzle to produce a perfect pre-roll is the joint filling machine. Futurola Knockbox is the product that defined the industry and it continues to be the best pre-roll machine in the market today.

Knockbox along with its add-ons allows you to fill multiple joints in one go. the pre-roll filling machines are designed to fill the joints as per your requirement at a given density. Most machines have a way for you to choose the density you need.

The mix is usually loaded into an upper compartment, the cones are loaded using a cone loader or manually into the lower compartment and a vibration table assembly fills the joints with the mix as per your need. The packing machines come in different sizes. With a Knockbox and a standard filling kit, you can fill a hundred joints in 2 minutes. That’s just the cone filling machine starter kit. With add-ons like the cone loader and a dutch crown device, you can roll joints at thousand-per-hour rates.

Using filling devices such as Knockbox maintains the integrity of the joints, fills it evenly, and can do it at scale. There are several sizes available in the market too. These are designed for the different sizes of available pre-rolled cones and to increase the number of joints that can be rolled in one go.

Closing Thoughts

Getting a perfect pre-roll right is not easy. Doing it manually can lead to inconsistencies if you are producing at scale. Not to mention the time it takes to produce at scale. Using the right equipment, strain and paper is the best way to ensure a great roll quality every time.

Using machinery designed to do the job will make it easier. Using it Smartly will help with the quality of the pre-rolls and will also help you do it at increased speeds. Grinders, trimmers, shredders, and cone rolling machines are integral to increasing your production capacities.

Futurola’s products are designed to help the industry produce at scale. With product warranties and detailed instructions, we make it easy for you to scale your pre-roll production and maintain quality. Get a quote from us today!

LEAVE A COMMENT

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.